- If a tiedown would be subject to cutting or abrasion, edge protection should be used.

- There should be no knots in the tiedowns.

- These all qualify as requirements.

- Components should be in proper working order.

Quote From Page 4 Of The CDL Manual:

Requirements for Securement System:

- In proper working order with no damaged or weakened components that affect their performance or reduce their working load limit.

- No knots.

- Attached and secured in a manner that prevents them from coming loose during transit.

- Able to be tightened by a driver of an in-transit vehicle.

- Located inboard of rub rails whenever practicable.

- Edge protection must be used when a tiedown would be subject to abrasion or cutting.

- 20% of cargo weight.

- 50% of cargo weight.

- 100% of cargo weight.

- 10,000 lbs.

Quote From Page 2 Of The CDL Manual:

Note: Friction mats provide a resistance to horizontal movement equal to 50% of the cargo weight that is resting on the mat.

- Less than 10,000 lbs

- Over 4,500 lbs

- Over 10,000 lbs

- 26,001 lbs

Quote From Page 1 Of The CDL Manual:

North American Cargo Securement Standard

What does the Standard cover? (Section 1.1)

- Commercial vehicles (including a combination of vehicles) that are operated on a highway and have a gross vehicle rating over 4,500 kg (10,000 lb.)

Vehicles

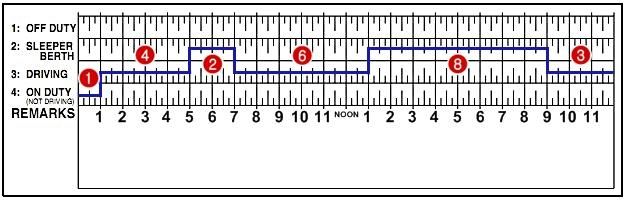

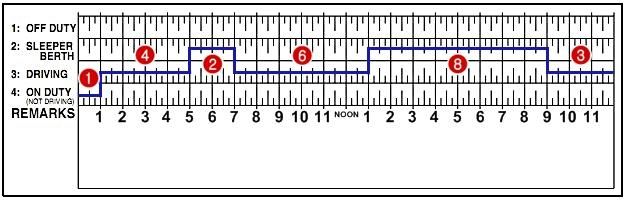

Is there a 14 hour rule violation on Day 2?

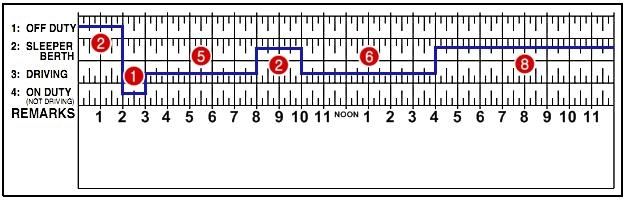

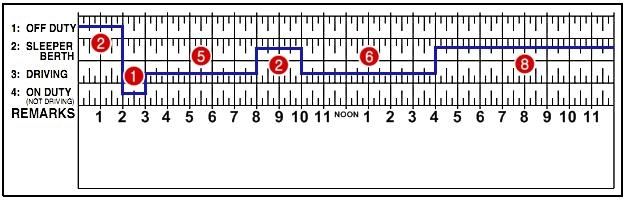

Day 1

Day 2

- Yes, at 7:00 a.m.

- Yes, at 1:00 a.m.

- No 14 hour rule violation occurs

- Yes, at 9:00 p.m.

Quote From Page 0 Of The CDL Manual:

Day 1

Day 2

Violations: There are no violations in this example.

Explanation - 11 Hour Limit: After 10 consecutive hours off duty, the driver had 11 hours of driving time available beginning at 2:00 a.m. on Day 1. The driver used those 11 hours by 4:00 p.m. on Day 1, when he or she entered the sleeper berth for 8 consecutive hours. Because the driver accumulated at least 10 hours of rest using a combination of at least 8 consecutive hours in a sleeper berth (4:00 p.m. to Midnight on Day 1) and another break of at least 2 consecutive hours (8:00 a.m. to 10:00 a.m. on Day 1), he or she was eligible for the split sleeper berth provision. This moves the calculation point to the end of the first of the two periods of rest, or 10:00 a.m. on Day 1. Starting the calculation from there, the driver accumulated another 10 hours of driving by 5:00 a.m. on Day 2. By 7:00 a.m. on Day 2, the driver accumulated another pair of qualifying breaks totaling at least 10 hours [4:00 p.m. to Midnight on Day 1 (8 hours) and 5:00 a.m. to 7:00 a.m. on Day 2 (2 hours)]. This moves the calculation point again, to the end of the first of the two breaks, or Midnight beginning Day 2. From there, the driver accumulated another 10 hours of driving by 1:00 p.m. on Day 2. The pattern of 8/2 split sleeper berth provisions continued, with no 11 hour violations.

Explanation - 30 Minute Break: On Day 1, the driver spent a total of 12 hours split between on duty and driving time. In order to continue driving beyond the 8th hour, a 30 minute break must be recorded. The calculation point on Day 1 is 2:00 a.m., so in order to continue driving after 10:00 a.m. (8 hours later), a minimum of 30 minutes must be spent off duty. In this example, the driver spent 2 hours in the sleeper berth from 8:00 a.m. to 10:00 a.m. and this satisfies the 30 minute break requirement, so no violation occurred. On Day 2, the driver first went on duty at midnight. In order to drive a CMV after 8:00 a.m. (8 hours later) a minimum of a 30 minute break off duty would be required. The driver met that requirement by taking a 2 hour break off duty (sleeper berth) break between 5:00 a.m. and 7:00 a.m. The hours spent driving between 9:00 p.m. and Midnight on Day 1 are also legal since an 8 hour break was taken between 1:00 p.m. and 9:00 p.m.

Explanation - 14 Hour Limit: Calculation of the 14 hour limit begins at 2:00 a.m. on Day 1. The driver accumulates 14 hours by 4:00 p.m. before entering the sleeper berth. Because the driver then met the requirements for the split sleeper berth provision, the calculation point moves to the end of the first qualifying break, or 10:00 a.m. on Day 1. So at Midnight leading into Day 2, the driver had accumulated 6 hours. By 7:00 a.m. on Day 2, the driver accumulated another pair of qualifying breaks totaling at least 10 hours and has not exceeded the 14 hour limit. This moves the calculation point again, to the end of the first of the two breaks, or Midnight leading into Day 2. From there, the driver accumulated 13 of 14 hours by 1:00 p.m. on Day 2. This split sleeper berth pattern continued, with no 14 hour limit violations.

- No more than 5 psi

- No more than 2 psi

- No more than 4 psi

- No more than 3 psi

Quote From Page 117 Of The CDL Manual:

With the engine running, build the air pressure to governed cut-out (100-125 psi). Shut off the engine, turn the electrical power on, chock your wheels, if necessary, release the tractor protection valve and parking brake (push in), fully apply the foot brake and hold it for one minute. Check the air gauge to see if the air pressure drops more than 3 pounds in 1 minute (single vehicle) or 4 pounds in 1 minute (combination vehicle) with brake applied. When brake is unapplied, air pressure drops more than 2 pounds in 1 minute with a single vehicle and 3 pounds in 1 minute in a combination vehicle.

TruckingTruth's Advice:

Be sure to memorize how much air loss is acceptable when the service brakes are applied and not applied.

- Initial methods of handling spills, fires and leaks of the materials.

- Information on the shipping name of the hazardous materials, risks to health, fire, and explosion

- How to safely handle incidents involving the material being shipped

- How to fight a fire started by the type of material being shipped

Quote From Page 93 Of The CDL Manual:

Shippers also must provide emergency response information to the motor carrier for each hazardous material being shipped. The emergency response information must be able to be used away from the motor vehicle and must provide information on how to safely handle incidents involving the material. It must include information on the shipping name of the hazardous materials, risks to health, fire, explosion, and initial methods of handling spills, fires and leaks of the materials.

Such information can be on the shipping paper or some other document that includes the basic description and technical name of the hazardous material. Or, it may be in a guidance book such as the Emergency Response Guidebook (ERG). Motor carriers may assist shippers by keeping an ERG on each vehicle carrying hazardous materials. The driver must provide the emergency response information to any federal, state or local authority responding to a hazardous materials incident or investigating one.

- Race the engine to improve engine braking

- Lightly ride the clutch during the grade

- To avoid engine damage, put the gear in neutral and coast down the hill

- Do not change gears while driving down a grade

Quote From Page 130 Of The CDL Manual:

When operating any commercial vehicle, do not ride the clutch, race the engine, change gears or coast while driving down the grade. At the bottom of the grade, be sure to cancel the 4-way flashers.

TruckingTruth's Advice:

Always slow down and be in proper gear before a downgrade and never change gears or coast during the downgrade.

- 5,130 lbs

- 11,300 lbs

- 9,200 lbs

- None of these

Quote From Page 14 Of The CDL Manual:

Size (in diameter):

- 7 mm (1/4 in):

- 8 mm (5/16 in):

- 10 mm (3/8 in):

- 11 mm (7/16 in):

- 13 mm (1/2 in):

- 16 mm (5/8 in):

- Chain Marks -

- Example 1:

- Example 2:

- Example 3:

Grade 70 Transport:

- 1430 kg (3150 lb)

- 2130 kg (4700 lb)

- 2990 kg (6600 lb)

- 3970 kg (8750 lb)

- 5130 kg (11300 lb)

- 7170 kg (15800 lb)

- Chain Marks -

- 7

- 70

- 700

- At any weigh station your logbook can be checked for any reason

- All of these answers are correct

- During a random traffic stop by any police officer

- Your carrier can audit your logbook anytime

Quote From Page 0 Of The CDL Manual:

Who Enforces HOS Regulations?

Law enforcement:

Generally, DOT officers are the ones who enforce HOS rules, although any police officer may inspect a driver's logbook. Individual states are responsible for maintaining weigh stations where drivers are pulled in for random vehicle and logbook inspections. Drivers may also be pulled over for random checks by police officers or DOT officials at any time and have their logbooks inspected. While it's not a frequent occurrence, chances are your logbook will be checked every now and then. Be ready for it at all times!

Carriers:

In addition to law enforcement and DOT officials, most carriers have their own company policies regarding logbooks. Not only do carriers want to ensure their drivers are being safe on the roadways, but carriers often receive audits from DOT officials and can be heavily fined if too many drivers have violations on their logs. A drivers logs are frequently reviewed by internal auditors for discrepancies or violations. A driver with too many violations might be warned, disciplined, or terminated (terminating a driver usually only occurs after several violations). The increased use of electronic logging devices (discussed later) has forced carriers to crack down on HOS violations even more.

TruckingTruth's Advice:

Your logbook can be checked virtually anytime. Never press your luck. Make sure your logbook is legal and up to date all the time.

- Less than 1 psi in 1 minute

- There should be no loss of any psi in 1 minute

- Less than 2 psi in 1 minute

- Less than 3 psi in 1 minute

Quote From Page 66 Of The CDL Manual:

Test air leakage rate: With a fully-charged air system (typically 125 psi), turn off the engine, release the service brake, and time the air pressure drop. The loss rate should be less than 2 psi in 1 minute for single vehicles and less than 3 psi in 1 minute for combination vehicles. Then apply 90 psi or more with the brake pedal. After the initial pressure drop, if the air pressure falls more than 3 psi in 1 minute for single vehicles and more than 4 psi for combination vehicles, the air loss rate is too much. Check for air leaks, and repair before driving the vehicle. Otherwise, you could lose your brakes while driving.

TruckingTruth's Advice:

You really need to memorize the allowable air leakage rates. This will very likely come up on your written exam and will come up again during the pre-trip exam. Here's what you should memorize (create flash cards if you have to).

With the service brakes released (not depressing the brake pedal):

- Air loss rate should be less than 2 psi in 1 minute for a single vehicle.

- Air loss rate should be less than 3 psi in 1 minute for combination vehicles (vehicles with a trailer).

With the service brakes depressed (pressing the brake pedal):

- Air loss rate should be less than 3 psi in 1 minute for a single vehicle.

- Air loss rate should be less than 4 psi in 1 minute for combination vehicles (vehicles with a trailer).

Be sure to have that memorized. Very important!!

) to help you understand the materials better and gain an understanding for how that knowledge will fit into the overall picture.

) to help you understand the materials better and gain an understanding for how that knowledge will fit into the overall picture.

TT On Facebook

TT On Facebook