Review Questions - Click On The Picture To Begin...

A container chassis vehicle is defined as:

- A vehicle especially built and fitted with locking devices for the transport of intermodal containers.

- A reusable, transportable enclosure that is especially designed with integral locking devices that secure it to a container chassis trailer to facilitate the efficient and bulk shipping and transfer of goods by, or between various modes of transport, such as highway, rail, sea, and air.

- A specialized container, primarily used to contain and transport materials in the waste, recycling, construction/demolition, and scrap industries, which are used in conjunction with specialized vehicles, in which the container isloaded and unloaded onto a tilt frame body by an articulating hook-arm.

- A structure, device, or another substantial article placed against an article to prevent it from tipping that may also prevent it from shifting.

Quote From The CDL Manual:

Container Chassis Vehicle:

A vehicle especially built and fitted with locking devices for the transport of intermodal containers.

Next

Who is responsible for inspecting securing devices and cargo within the first 50 miles?

- The D.O.T.

- The shipper.

- Your Moms.

- The driver.

Quote From The CDL Manual:

Inspect Cargo and Securing devices:

- Pre-Trip: Yes

- Within first 50 mi: Yes

- When duty status of driver changes: Yes

- At 3 hour intervals or every 150 mi, whichever is first: Yes

Prev

Next

The Aggregate Working Load Limit should, at minimum, be:

- Determined by the shipper.

- 80% of the weight of the cargo.

- 100% of the weight of the cargo.

- 50% of the weight of the cargo.

Quote From The CDL Manual:

How much should the Aggregate Working Load Limit be?

The aggregate working load limit of any securement system must be at least 50% of the weight of the cargo being secured.

Prev

Next

As part of their pre-trip cargo securement inspection, drivers should:

- Check for anything that will obscure their vision.

- All of these apply.

- Make sure cargo is properly secured.

- Inform carrier of any inadequate packaging.

Quote From The CDL Manual:

Driver inspection checklist:

Pre-Trip

- Make sure that cargo is properly distributed and adequately secured (in other words, according to the Standard).

- Make sure that all securement equipment and vehicle structures are in good working order and used consistent with their capability.

- Stow vehicle equipment.

- Make sure that nothing obscures front and side views or interferes with the ability to drive the vehicle or respond in an emergency.

-

Inform carrier if packaging is not adequate. For example:

- Banding is loose or not symmetrical on package.

- Banding attachment device(s) are inefficient.

- Wrapping is broken or ineffective.

- Pallets are broken.

Prev

Next

What is a cab shield?

- The depression formed between two cylindrical articles when they are laid with their eyes horizontal and parallel against each other.

- A vertical barrier placed directly behind the cab of a tractor to protect the cab in the event cargo should shift forward.

- A vertical barrier across the front of the deck of a vehicle to prevent forward movement of cargo.

- A structure, device, or another substantial article placed against or around an article to prevent horizontal movement of the article.

Quote From The CDL Manual:

The load carrying area of a truck, trailer, or intermodal container.

Prev

Next

What is the Aggregate WLL of the securement system for a load secured with 7 tiedowns: 3 rated at WLL of 4,000 lbs, 2 at 6,500, and 1 at 8,000?

- 33,000 lbs

- 10,000 lbs

- 16,500 lbs

- 8,250 lbs

Quote From The CDL Manual:

How do you calculate Aggregate Working Load Limit for tiedowns?

To calculate Aggregate Working Load limit, add together:

- 50% of the WLL of each end section of a tiedown that is attached to an anchor point.

- 50% of the WLL of each end section that is attached to the cargo

Prev

Next

A dunnage bag is:

- A structure, device, or another substantial article placed against or around an article to prevent horizontal movement of the article.

- A transverse load bearing structural component, particularly a part of a log bunk.

- An inflatable bag intended to fill otherwise empty space between articles of cargo, or between articles of cargo and the wall of the vehicle.

- A waterproof sheet used to cover cargo.

Quote From The CDL Manual:

Dunnage bag:

An inflatable bag intended to fill otherwise empty space between articles of cargo, or between articles of cargo and the wall of the vehicle.

Prev

Finish

Please select an option

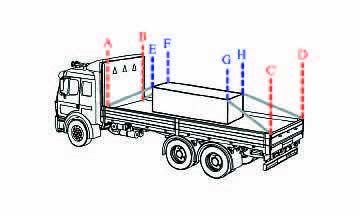

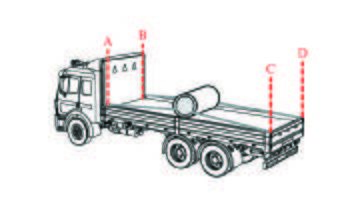

Related Cargo Securement Terms That Every Driver Should Know:

Related Cargo Securement Terms That Every Driver Should Know:

TT On Facebook

TT On Facebook