Review Questions - Click On The Picture To Begin...

- The emergency brakes

- The parking brakes

- The service brakes

- The driving brakes

Quote From The CDL Manual:

Air brake systems combine three braking systems: service, parking and emergency brake systems.

- 1. The service brake system applies and releases the brakes when you use the brake pedal during normal driving.

- 2. The parking brake system applies and releases the parking brakes when you use the parking brake control.

- 3. The emergency brake system uses parts of the service and parking brake systems to stop the vehicle in the event of a brake system failure.

TruckingTruth's Advice:

It is very important that you memorize the difference between the service brake, parking brake, and emergency brake. Study what the function is of each as you'll likely be asked about all 3 on the written exam. These are also terms you will need to know when out in the "real world."

- Manually operated air tank drains normally use a handle or a cable to drain the system

- All fluids from all air tanks drain into a central location which must be drained

- Automatic air tank drains always have to be drained manually as well

- Air tank drains should be forced into the open position during dry weather so that they drain throughout the day

Quote From The CDL Manual:

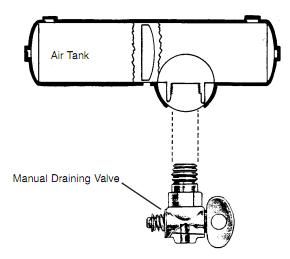

Air Tank Drains - Compressed air usually has some water and compressor oil in it, which is bad for the air brake system. For example, the water can freeze in cold weather and cause brake failure. The water and oil tend to collect in the bottom of the air tank. Be sure to drain the air tanks completely. Each air tank is equipped with a drain valve in the bottom. There are two types of drain valves:

- 1. Manually operated by turning a quarter turn or by pulling a cable. You must drain the tanks yourself at the end of each day of driving.

- 2. Automatic, in which the water and oil are automatically expelled. They may be equipped for manual draining as well.

The automatic types are available with electric heating devices. These help prevent freeze-up of the automatic drain in cold weather.

- Around 75 psi

- Around 150 psi

- Around 125 psi

- Around 100 psi

Quote From The CDL Manual:

When air tank pressure rises to the "cut-out" level (around 125 pounds per square inch, or "psi"), the governor stops the compressor from pumping air.

TruckingTruth's Advice:

Be sure to understand that the air compressor governor has one main purpose and that is to tell the air compressor when to pump air and when to stop pumping air. The air compressor governor will tell the air compressor to start supplying air (cut in) and when to stop supplying air (cut out).

- Cut in air pressure is usually when air pressure falls to about 100 psi.

- Cut out air pressure is usually when air pressure raises to about 125 psi

- Ensures that air never stops flowing into the air storage tanks

- Activates the emergency brakes when air pressure gets too high

- Detects any leaks in the airlines

- Controls when the air compressor will pump air into the air storage tanks

Quote From The CDL Manual:

The governor controls when the air compressor will pump air into the air storage tanks. When air tank pressure rises to the "cut-out" level (around 125 pounds per square inch, or "psi"), the governor stops the compressor from pumping air. When the tank pressure falls to the "cut-in" pressure (around 100 psi), the governor allows the compressor to start pumping again.

- Compressed air causes water to form and condense which is bad for the air brake system, especially if it freezes during cold weather

- Draining the air tanks helps to ensure the air pressure isn't building too high in the tanks

- The brake system sends water through the brake lines to flush the air lines out and the water needs to be drained through the air tanks before another system flush can occur

- Draining air tanks helps bring the air pressure lower which can then be used to test the air governor

Quote From The CDL Manual:

Air Tank Drains - Compressed air usually has some water and compressor oil in it, which is bad for the air brake system. For example, the water can freeze in cold weather and cause brake failure. The water and oil tend to collect in the bottom of the air tank. Be sure to drain the air tanks completely. Each air tank is equipped with a drain valve in the bottom. There are two types of drain valves:

- 1. Manually operated by turning a quarter turn or by pulling a cable. You must drain the tanks yourself at the end of each day of driving.

- 2. Automatic, in which the water and oil are automatically expelled. They may be equipped for manual draining as well.

The automatic types are available with electric heating devices. These help prevent freeze-up of the automatic drain in cold weather.

- They are used to supply air to the emergency brakes in the event of an air compressor failure

- They are used to transport air from the tractor to the trailer on combination vehicles

- They are used to hold compressed air for the air brake system

- They are used to supply air to the air compressor

Quote From The CDL Manual:

Air storage tanks are used to hold compressed air. The number and size of air tanks vary among vehicles. The tanks will hold enough air to allow the brakes to be used several times even if the compressor stops working.

TruckingTruth's Advice:

In an air brake system, emergency brakes naturally want to activate. It is the air pressure which holds the emergency brakes back and keeps them from activating. Therefor, air is not required for emergency brakes to function. Rather, if air is depleted from the air tanks, the emergency brakes will automatically engage.

- Every 3 months

- Once per week

- Once per day

- Once per month

Quote From The CDL Manual:

You must drain the tanks yourself at the end of each day of driving.

- Air compressors may have their own oil supply or be lubricated by engine oil

- The air compressor pumps air into the air storage tanks

- Air compressors are always air cooled

- The air compressor is connected to the engine through gears or a V-belt

Quote From The CDL Manual:

The air compressor pumps air into the air storage tanks (reservoirs). The air compressor is connected to the engine through gears or a V-belt. The compressor may be air cooled or may be cooled by the engine cooling system. It may have its own oil supply or be lubricated by engine oil. If the compressor has its own oil supply, check the oil level before driving.

- A system which applies and releases the brakes when you use the brake pedal during normal driving

- A system which applies and releases the parking brakes when you use the parking brake control

- A system used by mechanics during servicing do deactivate the emergency brakes

- A system which uses parts of the service and parking brake systems to stop the vehicle in the event of a brake system failure.

Quote From The CDL Manual:

Air brake systems combine three braking systems: service, parking and emergency brake systems.

- 1. The service brake system applies and releases the brakes when you use the brake pedal during normal driving.

- 2. The parking brake system applies and releases the parking brakes when you use the parking brake control.

- 3. The emergency brake system uses parts of the service and parking brake systems to stop the vehicle in the event of a brake system failure.

TruckingTruth's Advice:

It is vital that you learn the difference between the following definitions:

- Service Brake

- Parking Brake

- Emergency Brake

Memorize each definition and be sure you understand how each of these differ. Not only will this be critically important to passing the air brakes endorsement test but it is terminology you'll need to understand in the real world.

- The air compressor will begin supplying air to the air storage tanks

- The air compressor will begin releasing air from the air storage tanks

- The air compressor will stop supplying air to the air storage tanks

- The air compressor will stop releasing air from the air storage tanks

Quote From The CDL Manual:

Air Compressor - The air compressor pumps air into the air storage tanks (reservoirs). The air compressor is connected to the engine through gears or a V-belt. The compressor may be air cooled or may be cooled by the engine cooling system. It may have its own oil supply or be lubricated by engine oil. If the compressor has its own oil supply, check the oil level before driving.

Air Compressor Governor - The governor controls when the air compressor will pump air into the air storage tanks. When air tank pressure rises to the "cut-out" level (around 125 pounds per square inch, or "psi"), the governor stops the compressor from pumping air. When the tank pressure falls to the "cut-in" pressure (around 100 psi), the governor allows the compressor to start pumping again.

TruckingTruth's Advice:

Be sure to understand how the air compressor and air compressor governor both work. The air compressor governor does not supply air, rather, it tells the air compressor when it should or shouldn't be supplying air to the air storage tanks.

- They are used to transfer air from the air tank to the brake chambers

- They allow water to be released from the air tanks

- They allow oil to be inserted into the air tanks

- They allow air to be released when the air pressure builds too high

Quote From The CDL Manual:

Air Tank Drains - Compressed air usually has some water and compressor oil in it, which is bad for the air brake system. For example, the water can freeze in cold weather and cause brake failure. The water and oil tend to collect in the bottom of the air tank. Be sure to drain the air tanks completely. Each air tank is equipped with a drain valve in the bottom. There are two types of drain valves:

- 1. Manually operated by turning a quarter turn or by pulling a cable. You must drain the tanks yourself at the end of each day of driving.

- 2. Automatic, in which the water and oil are automatically expelled. They may be equipped for manual draining as well.

The automatic types are available with electric heating devices. These help prevent freeze-up of the automatic drain in cold weather.

- Air storage tanks are used to hold compressed air

- Air storage tanks release excess air pressure in the brake system

- Air storage tanks are used to keep the parking brakes active while stopped

- Air storage tanks transfer air from the tractor to the trailer on combination vehicles

Quote From The CDL Manual:

Air storage tanks are used to hold compressed air. The number and size of air tanks vary among vehicles. The tanks will hold enough air to allow the brakes to be used several times even if the compressor stops working.

- It may have its own oil supply or be lubricated by engine oil

- It sucks air out of the air storage tanks (reservoirs)

- It has a separate fuel tank which must be filled every 100 to 200 miles

- It does not connect to the main engine and runs off of a separate independent motor

Quote From The CDL Manual:

The air compressor pumps air into the air storage tanks (reservoirs). The air compressor is connected to the engine through gears or a V-belt. The compressor may be air cooled or may be cooled by the engine cooling system. It may have its own oil supply or be lubricated by engine oil. If the compressor has its own oil supply, check the oil level before driving.

- Supplies an alcohol mixture to the brake pads, keeping them clean from foreign debris

- Injects alcohol into the air compressor, keeping moving parts clean and free from debris

- Helps reduce the risk of ice in air brake valves and other parts during cold weather

- Keeps the air lines free from sand, dirt, and dust

Quote From The CDL Manual:

Alcohol Evaporator - Some air brake systems have an alcohol evaporator to put alcohol into the air system. This helps reduce the risk of ice in air brake valves and other parts during cold weather. Ice inside the system can make the brakes stop working.

Check the alcohol container and fill up as necessary every day during cold weather. Daily air tank drainage is still needed to get rid of water and oil (unless the system has automatic drain valves).

- Around 75 psi

- Around 100 psi

- Around 50 psi

- Around 125 psi

Quote From The CDL Manual:

When the tank pressure falls to the "cut-in" pressure (around 100 psi), the governor allows the compressor to start pumping again.

TruckingTruth's Advice:

Make sure you memorize the air pressure for when the governor will "cut in" and "cut out" as you will need to know this for the written exam, the pre-trip exam, and in the real world while checking your gauges going down the road.

TT On Facebook

TT On Facebook