Note: Your are not logged in. We can not keep your scores or track your progress unless you Register and Log In

Securing Pipe with an Inside Diameter Up to 1143 mm (45 in) (continued)

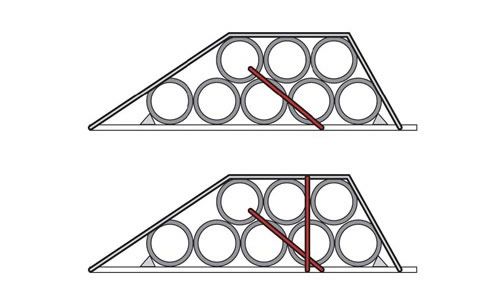

Requirements for stabilizing the top tier

If the first pipe of a group in the top tier is not at the front of the tier beneath:

Attach an additional tie-down that runs rearward at an angle not more than 45 to the horizontal when viewed from the side of the vehicle, whenever practical.

Pass tie-down either through the front pipe of the upper tier or outside the front pipe and over both longitudinal tie-downs.

Special Circumstances: Securing Large Pipe with an Inside Diameter over 1143 mm (45 in)

Requirements for stabilizing the pipe

Arrange the load properly

Immobilize the front and rear pipe with on of the following methods:

- Blocking

- Wedges

- Vehicle end structure

- Stakes

- Locked pipe unloader

- Other equivalent means

For all other pipe, use additional blocks and/or wedges that are nailed in place.

Requirements for securing the pipe

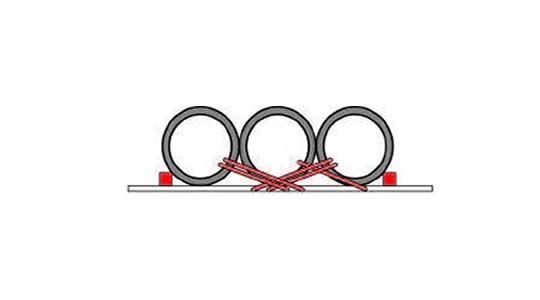

Secure each pipe with tie-downs through the pipe.

Run at least one tie-down through each pipe in the front half of the load. This includes the middle one if there are an odd number. The tie-down must run rearward at an angle not more than 45° with the horizontal when viewed from the side of the vehicle, whenever practicable.

Run at least one tie-down through each pipe in the rear half of the load. The tie-down must run forward at an angle not more than 45° with the horizontal when viewed from the side of the vehicle, whenever practicable. This holds each pipe firmly in contact with adjacent pipe.

Run at least two tie-downs through the front and rear pipe if they are not also in contact with vehicle end structure, stakes, a locked pipe unloader, or other equivalent means.

Run at least two tie-downs through the front and rear pipe if they are not also in contact with one of the following:

- Either the vehicle end structure

- Or the stakes

- Or a locked pipe unloader

- Or other equivalent means.

Note: If only one pipe is transported, or if several pipes are transported without contact between other pipes, the requirements of this section apply to each pipe as a single front and rear article. Tie-downs must be used through that pipe.

Multiple-Choice Questions:

What is the maximum angle recommended for tiedowns securing cement pipe loaded crosswise, relative to the deck?

- It doesn't matter

- 180 degrees

- 45-90 degrees

- 45 degrees

If the first pipe of a group in the top tier is not at the front of the tier beneath:

Attach an additional tiedown that runs rearward at an angle not more than 45 to the horizontal when viewed from the side of the vehicle, whenever practical.

Pass tiedown either through the front pipe of the upper tier or outside the front pipe and over both longitudinal tiedowns.

When securing concrete pipe with a diameter of more than 45 inches loaded crosswise, how many tiedowns are required through each pipe at minimum?

- 1

- It depends on the weight of the pipe.

- 3

- 2

Requirements for securing the pipe

Secure each pipe with tiedowns through the pipe.

Run at least one tiedown through each pipe in the front half of the load. This includes the middle one if there are an odd number. The tiedown must run rearward at an angle not more than 45� with the horizontal when viewed from the side of the vehicle, whenever practicable.

Run at least one tiedown through each pipe in the rear half of the load. The tiedown must run forward at an angle not more than 45� with the horizontal when viewed from the side of the vehicle, whenever practicable. This holds each pipe firmly in contact with adjacent pipe.

When securing concrete pipe over 45 inches loaded crosswise, which direction must the tiedowns on the rear half of the load run?

- Straight up and down.

- It doesn't matter.

- Forward

- Rearward

Requirements for securing the pipe

Secure each pipe with tiedowns through the pipe.

Run at least one tiedown through each pipe in the front half of the load. This includes the middle one if there are an odd number. The tiedown must run rearward at an angle not more than 45� with the horizontal when viewed from the side of the vehicle, whenever practicable.

Run at least one tiedown through each pipe in the rear half of the load. The tiedown must run forward at an angle not more than 45� with the horizontal when viewed from the side of the vehicle, whenever practicable. This holds each pipe firmly in contact with adjacent pipe.

When securing concrete pipe over 45 inches loaded crosswise, which direction must the tiedowns on the front half of the load run?

- Forward

- Straight up and down

- Rearward

- It doesn't matter

Requirements for securing the pipe

Secure each pipe with tiedowns through the pipe.

Run at least one tiedown through each pipe in the front half of the load. This includes the middle one if there are an odd number. The tiedown must run rearward at an angle not more than 45� with the horizontal when viewed from the side of the vehicle, whenever practicable.

Run at least one tiedown through each pipe in the rear half of the load. The tiedown must run forward at an angle not more than 45� with the horizontal when viewed from the side of the vehicle, whenever practicable. This holds each pipe firmly in contact with adjacent pipe.

When loaded cement pipe over 45 inches in diameter, which pipes should be blocked, wedged, or otherwise immobilized?

- It depends on the weight of the load.

- Rear only.

- Front and rear.

- Front only.

Immobilize the front and rear pipe with on of the following methods:

- Blocking

- Wedges

- Vehicle end structure

- Stakes

- Locked pipe unloader

- Other equivalent means

Complete!

You can Return To The Table Of Contents

TT On Facebook

TT On Facebook