Note: Your are not logged in. We can not keep your scores or track your progress unless you Register and Log In

Containing, Immobilizing, and Securing Cargo

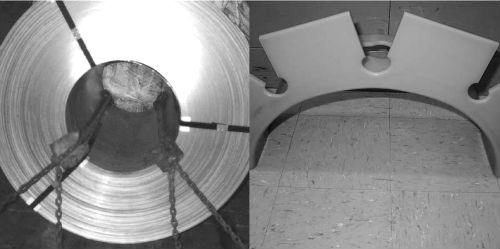

Edge protection

Edge protection must be used if a tie-down could be cut or torn when touching an article of cargo. The edge protection itself must also resist crushing, cutting, and abrasion.

Left: Use of edge protection Right: Edge protector

Blocking and bracing

Material used

The material used for blocking or bracing and as chocks and cradles must be strong enough to withstand being split or crushed by the cargo or tie-downs.

This requirement also applies to any material used for dunnage.

If wood is used:

- Hardwood is recommended.

- It should be properly seasoned.

- It should be free from rot or decay, knots, knotholes, and splits.

The grain should run lengthwise when using wood for blocking or bracing.

Containing, Immobilizing, and Securing Cargo

To correctly contain, immobilize, or secure cargo, you need to know about:

- Three ways to transport cargo

- Loading the cargo properly

- Restraining the cargo correctly

- Using adequate securing devices

- Aggregate Working Load Limit

Note: These requirements cover many types of cargo except commodities in bulk that lack structure or fixed shape (for example, liquids, gases, grain, sand, gravel, aggregate, liquid concrete). Commodities that are transported in the structure of a commercial motor vehicle such as a tank, hopper, or box.

Note: The Standard sets forth specific securement requirements for certain loads. When transporting these commodities, you must use the specific requirements for that commodity.

- Concrete Pipe Loaded Crosswise on a Platform Vehicle

- Dressed Lumber and Similar Building Products

- Logs

- Metal Coils

- Paper Rolls

- Automobiles, Light Trucks, and Vans

- Roll-on/Roll-off, Hook-Lift and Intermodal containers

- Heavy Vehicles, Equipment, and Machinery

- Flattened or Crushed Vehicles

- Large Boulders

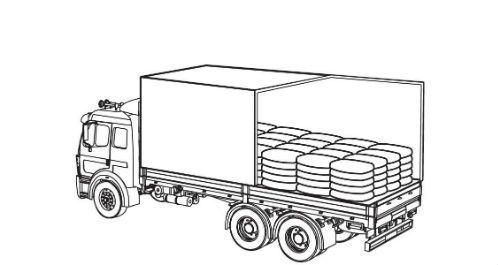

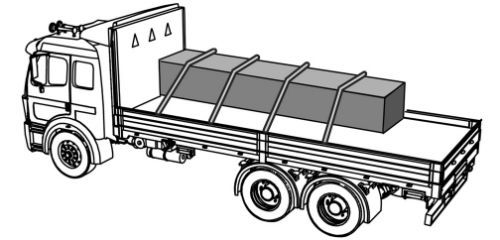

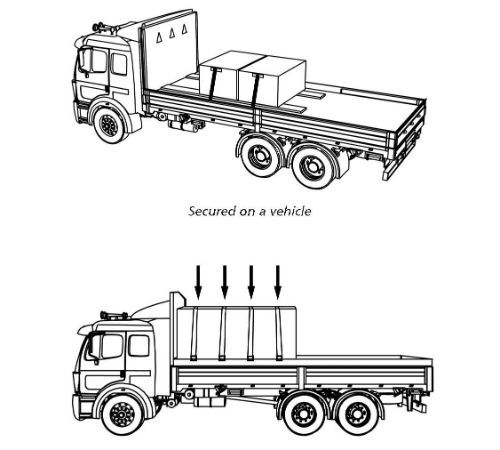

Three ways to transport cargo

All types of cargo must meet one of three conditions:

Condition 1: Cargo is fully contained by structures of adequate strength.

Cargo cannot shift or tip

Cargo is restrained against horizontal movement by vehicle structure or by other cargo. Horizontal movement includes forward, rearward, and side to side.

Note: If the cargo is contained in a sided vehicle, the vehicle structure MUST be strong enough to withstand the forces described earlier.

- Forward force: 0.8 g (80%)

- Rearward force: 0.5.g (50%)

- Sideways force: 0.5 g (50%)

Condition 2:

Cargo is immobilized by structures adequate strength or a combination of structure, blocking, and bracing to prevent shifting or tipping.

Condition 3: To prevent shifting or tipping, cargo is immobilized or secured on or within a vehicle by tiedowns along with:

- Blocking.

- Bracing.

- Friction mats.

- Other cargo.

- Void fillers.

- Combination of these.

Related Cargo Securement Terms That Every Driver Should Know:

Related Cargo Securement Terms That Every Driver Should Know:

-

Friction mat:

A device placed between the deck of a vehicle and car or between articles of cargo, intended to provide greater friction than exists naturally between these surfaces.

-

Void Filler:

Material used to fill a void between articles of cargo and the structure of the vehicle that has sufficient strength to prevent movement of the articles of cargo.

-

Aggregate Working Load Limit:

The summation of the working load limits or restraining capacity of all devices used to secure an article on a vehicle.

Multiple-Choice Questions:

If the cargo is fully contained in a sided vehicle, what is the minimum requirement for withstanding sideways force?

- 0.8g (80% of cargo weight)

- 0.2g (20% of cargo weight)

- 0.5g (50% of cargo weight)

- 0.7g (70% of cargo weight)

Note: If the cargo is contained in a sided vehicle, the vehicle structure MUST be strong enough to withstand the forces described earlier.

- Forward force: 0.8 g (80%)

- Rearward force: 0.5.g (50%)

- Sideways force: 0.5 g (50%)

A device placed between the deck of a vehicle and car or between articles of cargo, intended to provide greater friction than exists naturally between these surfaces is:

- A chock.

- A friction mat.

- A cleat.

- Void filler.

Friction mat:

A device placed between the deck of a vehicle and car or between articles of cargo, intended to provide greater friction than exists naturally between these surfaces.

Aggregate Working Load Limit is defined as:

- The summation of the working load limits or restraining capacity of all devices used to secure an article on a vehicle.

- The maximum weight of a load of rocks that a securement device can withstand.

- The maximum load that may be applied to a component of a cargo securement system during normal service, usually assigned by the manufacturer of the component.

- A combination of securing devices which form an assembly that attaches cargo to, or restrains cargo on, a vehicle or trailer, and is attached to anchor point(s).

Aggregate Working Load Limit:

The summation of the working load limits or restraining capacity of all devices used to secure an article on a vehicle.

Which of the following is not a requirement of wood used as blocking or bracing?

- It should be free of decay and structural defects.

- Hardwood is recommended.

- It should be painted.

- It should be properly seasoned.

If wood is used:

- Hardwood is recommended.

- It should be properly seasoned.

- It should be free from rot or decay, knots, knotholes, and splits.

A sided vehicle containing cargo weighing 35,980 lbs must be able to withstand a rearward force of at least:

- 10,000 lbs

- 28,784 lbs

- 36,000 lbs

- 17,990 lbs

Note: If the cargo is contained in a sided vehicle, the vehicle structure MUST be strong enough to withstand the forces described earlier.

- Forward force: 0.8 g (80%)

- Rearward force: 0.5.g (50%)

- Sideways force: 0.5 g (50%)

Complete!

You can Return To The Table Of Contents

TT On Facebook

TT On Facebook