Note: Your are not logged in. We can not keep your scores or track your progress unless you Register and Log In

Tie-Down Requirements

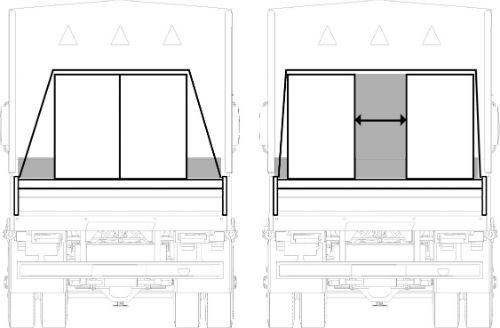

For articles of cargo placed beside each other and secured by side-to-side tiedowns:

Either place them in direct contact with each other,

Or prevent them from shifting towards each other in transit by using blocking or filling the space with other cargo.

Some articles have a tendency to roll. To prevent rolling, provide more than one point of contact:

Lift the cargo off the deck AND/OR

Place chocks, wedges, a cradle, or other equivalent means that prevent rolling. These must be secured to the deck.

The method used to prevent rolling must not become unfastened or loose while the vehicle is in transit.

Prevent tipping or shifting by bracing the cargo.

Immobilizing, and Securing Cargo: Restraining the cargo correctly.

How many tiedowns are required?

If cargo is not prevented from forward movement (for example, by the headboard, bulkhead, other cargo, or tiedown attached to the cargo), secure the cargo according to the following requirements:

-

If load is 5ft or shorter, 1,100 lbs or lighter:

Minimum number of tiedowns: 1

-

If load is 5ft or shorter, over 1,100 lbs:

Minimum number of tiedowns: 2

-

If load is more than 5ft but less than 10ft:

Minimum number of tiedowns: 2

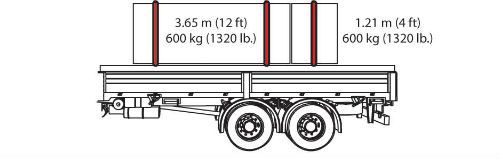

When cargo is prevented from forward movement (for example, by the headboard, bulkhead, other cargo, or tiedown), secure the cargo according to the following requirements:

All Cargo:

1 tiedown for every 10 ft, or part thereof.

Note: A vehicle transporting one or more articles of cargo such as, but not limited to, machinery or fabricated structural items (e.g., steel or concrete beams, crane booms, girders, and trusses, etc.) which, because of their design, size, shape, or weight, must be fastened by special methods.

However, any article of cargo carried on that vehicle must be securely and adequately fastened to the vehicle.

How should tiedowns be attached?

Tiedowns can be used in two ways:

-

Attached to the cargo:

- Tiedowns attached to the vehicle and attached to the cargo.

- Tiedowns attached to the vehicle, pass through or aroundan article of cargo, and then are attached to the vehicle again.

-

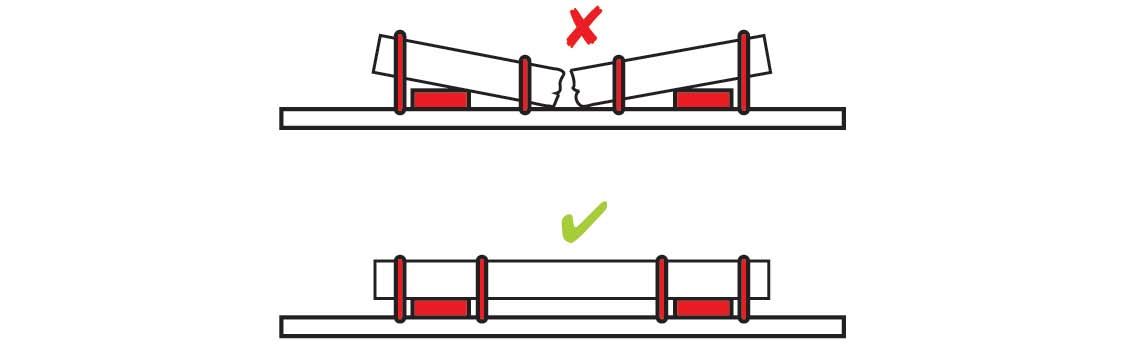

Pass over the cargo:

- Tiedowns attached to the vehicle, passed over the cargo, and then attached to the vehicle again.

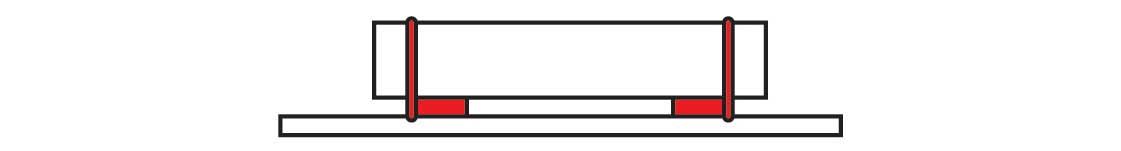

Tiedown placement:

Place the tiedown as close as possible to the spacer.

Position the tiedowns as symetrically as possible over the length of the article.

Position the tiedowns to preserve the integrity of the article.

Related Cargo Securement Terms That Every Driver Should Know:

Related Cargo Securement Terms That Every Driver Should Know:

-

Rub Rail:

A rail along the side of a vehicle that protects the side of the vehicle from impacts.

-

Bracing:

A structure, device, or another substantial article placed against an article to prevent it from tipping that may also prevent it from shifting.

-

Working Load Limit (WLL):

The maximum load that may be applied to a component of a cargo securement system during normal service, usually assigned by the manufacturer of the component.

Multiple-Choice Questions:

Working Load Limit (WLL)is defined as:

- The number of hours that a tiedown can be used.

- The maximum load that may be applied to a component of a cargo securement system during normal service, usually assigned by the manufacturer of the component.

- The summation of the working load limits or restraining capacity of all devices used to secure an article on a vehicle.

- The acceleration due to gravity, 9.823 m/sec2 (32.2 ft/sec2).

Working Load Limit (WLL):

The maximum load that may be applied to a component of a cargo securement system during normal service, usually assigned by the manufacturer of the component.

When using tiedowns for securing cargo, what is the general rule regarding cargo length.

- 1 tiedown for every 10 ft, or part thereof.

- 1 tiedown for every 5 ft, or part thereof.

- 1 tiedown for every 15 ft, or part thereof.

- 2 tiedowns for every 10 ft, or part thereof.

When cargo is prevented from forward movement (for example, by the headboard, bulkhead, other cargo, or tiedown), secure the cargo according to the following requirements:

All Cargo:

1 tiedown for every 10 ft, or part thereof.

Which of the following is not a method of securing side-by-side cargo?

- Make sure it is leaning forward.

- Use some kind of blocking to prevent shifting.

- Fill the empty space between with other cargo.

- Place them in direct contact with each other.

For articles of cargo placed beside each other and secured by side-to-side tiedowns:

Either place them in direct contact with each other,

Or prevent them from shifting towards each other in transit by using blocking or filling the space with other cargo.

What is a rub rail?

- A strip of material that may be used to unitize articles and is tensioned and clamped or crimped back upon itself. (same as "Strapping")

- A rail along the side of a vehicle that protects the side of the vehicle from impacts.

- A platform or tray on which cargo is placed so that it can be handled as an article. (Same as "Skid")

- A device placed between the deck of a vehicle and car or between articles of cargo, intended to provide greater friction than exists naturally between these surfaces.

Rub Rail:

A rail along the side of a vehicle that protects the side of the vehicle from impacts.

What is the minimum number of tiedowns to use on a load 4ft 7in long, and weighing 1,237 lbs?

- 4

- 2

- 3

- 1

-

If load is 5ft or shorter, 1,100 lbs or lighter:

Minimum number of tiedowns: 1

-

If load is 5ft or shorter, over 1,100 lbs:

Minimum number of tiedowns: 2

-

If load is more than 5ft but less than 10ft:

Minimum number of tiedowns: 2

Complete!

You can Return To The Table Of Contents

TT On Facebook

TT On Facebook