Note: Your are not logged in. We can not keep your scores or track your progress unless you Register and Log In

Securement Requirements for Individual Metal Coils with Eyes Lengthwise

There are three options for safely securing individual coils that are loaded with their eyes lengthwise.

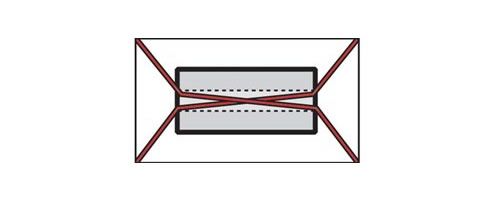

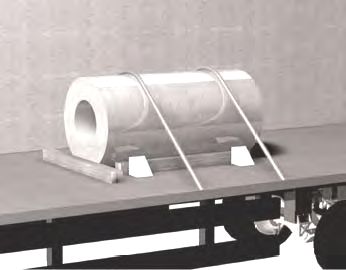

Securement Option #1:

Step #1: Support the coil above the deck to prevent the coil from rolling.

Step #2: Attach at least one direct tie-down on each diagonal through the eye of the coil making an angle not more than 45 degrees with the floor of the vehicle when viewed from the side.

Attach at least one indirect tie-down side-to-side over the top of the coil.

Use blocking or friction mats to prevent forward movement.

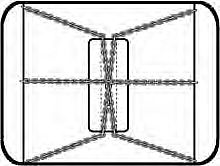

Securement Option #2:

Same as Option #1, except the direct tie-downs are straight instead of diagonal.

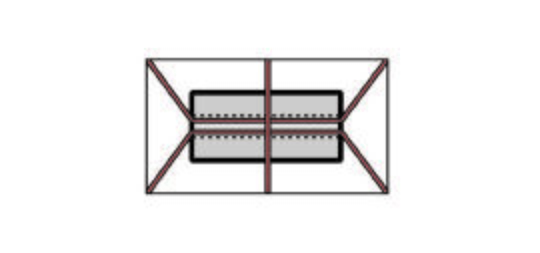

Securement Option #3:

This option is the same as Option #1 and #2, except the two direct tie-downs are replaced with two indirect tie-downs over the front and rear parts of the coil.

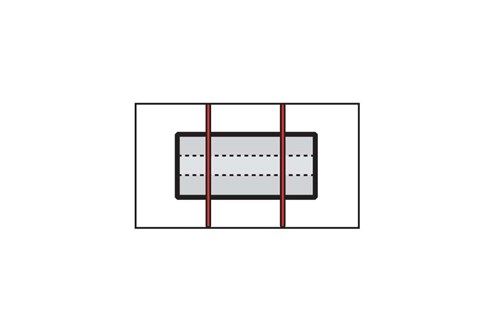

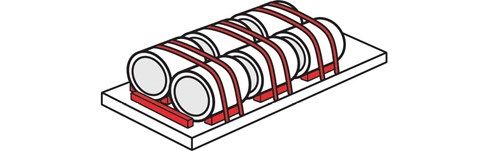

Securement Requirements for a Row of Metal Coils with Eyes Lengthwise:

A row of coils is made up of three or more coils loaded in like mode and in a line. The requirements for securing a row of coils is similar to securing individual coils (Option #3).

Step #1:

Support the coils above the deck to prevent the coils from rolling. The means to support the coils (for example, timbers, chocks or wedges, a cradle, etc.) must not become unfastened or loose while the vehicle is in transit.

Step #2:

Attach at least two direct tie-downs over each coil or side-by-side row.

Step #3:

Use blocking or friction mats to prevent front-to-back movement in the forward direction.

Securement Requirements for Metal Coils in Sided Vehicles or Intermodal Containers without Anchor Points:

Coils must be prevented from horizontal movement or from tipping, by use of the following:

- Friction mats

- System of blocking and bracing

- Tie-downs and blocking

- Tie-downs and bracing

The carrier/driver must ensure that the securement system meets the performance criteria requirements (Section 1).

Multiple-Choice Questions:

When securing a metal coil with eyes lengthwise, all of the following are steps for securement option #1 except for:

- Support the coil above the deck.

- Attach at least one tiedown through the eye diagonally each way.

- These are all part of method #1.

- Attach at least one indirect tiedown side-to-side over the top.

Step #1: Support the coil above the deck to prevent the coil from rolling.

Step #2: Attach at least one direct tiedown on each diagonal through the eye of the coil making an angle not more than 45 degrees with the floor of the vehicle when viewed from the side.

Attach at least one indirect tiedown side-to-side over the top of the coil.

Use blocking or friction mats to prevent forward movement.

A row of metal coils loaded with eyes lengthwise requires how many direct tiedowns over each side-by-side row or coil?

- One

- It depends on the size of the coils.

- Four

- Two

Step #2:

Attach at least two direct tiedowns over each coil or side-by-side row.

Option #3 for a single metal coil with eyes lengthwise requires:

- Two direct tiedowns on either side straight through the eye.

- Two indirect tiedowns over the front and rear parts of the coil.

- One direct tiedown on each diagonal through the eye of the coil

- At least one indirect tiedown side-to-side over the top of the coil.

Securement Option #2:

Same as Option #1, except the direct tiedowns are straight instead of diagonal.

Complete!

You can Return To The Table Of Contents

TT On Facebook

TT On Facebook