Note: Your are not logged in. We can not keep your scores or track your progress unless you Register and Log In

SECTION 2: GENERAL PROVISIONS AND REQUIREMENTS

Failure Modes for Securement Systems:

When cargo is subjected to the forces in the performance criteria (Section 1), and when the securement system is not adequate, the system will fail in one of the following three failure modes:

- Rolling

- Sliding

- Tipping

Objectives for Securement Equipment and Devices:

It is the responsibility of drivers, shippers, carriers and enforcement personnel to ensure that all securement equipment, devices and the vehicle structure are in good working order and are used within their capability.

Securement systems are made up of the following categories:

- Category 1- Vehicle Structure and Anchor Points, Cargo Securement Responsibility and Cab Shields

- Category 2 - Securement Methods

- Category 3 - Devices, Assemblies and Components

- Category 4 - Dunnage Materials

CATEGORY 1

Vehicle Structure and Anchor Points:

The vehicle must be strong enough to resist the forces in the performance criteria (Section 1). The vehicle must be appropriate for the cargo it is to transport, or it must be adapted to be suitable by using fittings, fixtures, dunnage, cribbing or other means.

Cargo Securement Responsibility:

According to federal and state regulations, the carrier and driver are responsible for ensuring that the vehicles, anchor points and other securement components are in good working order, with no obvious signs of damage. The driver is also required to conduct a pre-trip inspection by other operating regulations.

Roadside inspections are conducted in accordance with federal, state and provincial laws. If securement equipment fails inspection, it is likely that the vehicle may be placed out-of-service, and the motor carrier and/or the driver may be fined.

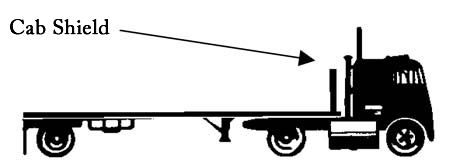

Cab Shields:

A cab shield is a safety device mounted to the tractor; it is not a part of the cargo securement system.

CATEGORY 2

Securement Method:

Because metal coils are different in size, shape, weight and other properties, the shipper and the carrier should devise a securement method that is suited to the characteristics of the cargo, and that meets the performance criteria (Section 1).

CATEGORY 3

Securement Devices, Assemblies and Components - Packaging:

If a package collapses in transit after the tiedowns are tensioned, the tiedowns become loose and parts of the load may fall from the vehicle. Because the shipper usually packages cargo, the shipper needs to make sure that the packages are strong enough to withstand the forces during transport.

- The forward force (80% of the cargo weight) represents braking while driving straight ahead.

- The rearward force (50% of the cargo weight) represents vehicle acceleration or braking in reverse.

- The side-to-side or lateral force (50% of the cargo weight) represents traveling on a curve, ramp or changing lanes.

- The vertical force (20% of the cargo weight)) represents cargo vibration during transport. This requirement is satisfied when the cargo is "Fully Contained"

After the driver completes an inspection, it is the responsibility of the driver to inform the carrier that the packaging is not adequate.

- All securing devices must be used in accordance with the manufacturer's instructions.

- Where practicable, all tiedowns must be inside of the rub rail.

- Edge protection must be used. The edge protection must resist abrasion, cutting and crushing.

- Tiedowns and securing devices must not contain knots.

- When necessary, tiedowns must be repaired according to applicable standards or the manufacturer's instructions.

Cargo Securement Terms That Truck Drivers Should Know:

Cargo Securement Terms That Truck Drivers Should Know:

-

Anchor point:

Part of the structure, fitting, or attachment on a vehicle or cargo to which a tiedown is attached.

-

Cab shield:

A vertical barrier placed directly behind the cab of a tractor to protect the cab in the event cargo should shift forward.

-

Edge protector:

A device placed on the exposed edge of an article to distribute tiedown forces over a larger area of cargo than the tiedown itself, to protect the tie-down and/or cargo from damage, and to allow the tiedown to slide freely when being tensioned.

-

Dunnage bag:

An inflatable bag intended to fill otherwise empty space between articles of cargo, or between articles of cargo and the wall of the vehicle.

Multiple-Choice Questions:

What is a cab shield?

- A structure, device, or another substantial article placed against or around an article to prevent horizontal movement of the article.

- A vertical barrier placed directly behind the cab of a tractor to protect the cab in the event cargo should shift forward.

- A short piece of material, usually wood, nailed to the deck to reinforce blocking.

- A rail along the side of a vehicle that protects the side of the vehicle from impacts.

Cab shield:

A vertical barrier placed directly behind the cab of a tractor to protect the cab in the event cargo should shift forward.

Who is responsible for ensuring that the vehicles, anchor points and other securement components are in good working order?

- The driver and shipper.

- The shipper and carrier.

- The carrier and driver

- The DOT and the FMCSA.

Cargo Securement Responsibility:

According to federal and state regulations, the carrier and driver are responsible for ensuring that the vehicles, anchor points and other securement components are in good working order, with no obvious signs of damage. The driver is also required to conduct a pre-trip inspection by other operating regulations.

A device placed on the exposed edge of an article to distribute tiedown forces over a larger area of cargo than the tiedown itself, to protect the tie-down and/or cargo from damage, and to allow the tiedown to slide freely when being tensioned is a:

- Chock.

- Edge protector:

- Bulkhead.

- Pallet.

Edge protector:

A device placed on the exposed edge of an article to distribute tiedown forces over a larger area of cargo than the tiedown itself, to protect the tie-down and/or cargo from damage, and to allow the tiedown to slide freely when being tensioned.

A load weighing 41,500 lbs requires securement against rearward force of:

- 20,000 lbs.

- 41,500 lbs.

- 10,000 lbs.

- 20,750 lbs.

- The forward force (80% of the cargo weight) represents braking while driving straight ahead.

- The rearward force (50% of the cargo weight) represents vehicle acceleration or braking in reverse.

- The side-to-side or lateral force (50% of the cargo weight) represents traveling on a curve, ramp or changing lanes.

- The vertical force (20% of the cargo weight)) represents cargo vibration during transport. This requirement is satisfied when the cargo is "Fully Contained"

An anchor point is defined as:

- A structure, device, or another substantial article placed against an article to prevent it from tipping that may also prevent it from shifting.

- A tapered or wedge-shaped piece used to secure round articles against rolling.

- A vertical barrier across a vehicle to prevent forward movement of cargo.

- Part of the structure, fitting, or attachment on a vehicle or cargo to which a tiedown is attached.

Anchor point:

Part of the structure, fitting, or attachment on a vehicle or cargo to which a tiedown is attached.

A dunnage bag is:

- Material used to fill a void between articles of cargo and the structure of the vehicle that has sufficient strength to prevent movement of the articles of cargo.

- An inflatable bag intended to fill otherwise empty space between articles of cargo, or between articles of cargo and the wall of the vehicle.

- A device placed between the deck of a vehicle and car or between articles of cargo, intended to provide greater friction than exists naturally between these surfaces.

- A waterproof sheet used to cover cargo.

Dunnage bag:

An inflatable bag intended to fill otherwise empty space between articles of cargo, or between articles of cargo and the wall of the vehicle.

Complete!

You can Return To The Table Of Contents

TT On Facebook

TT On Facebook