Note: Your are not logged in. We can not keep your scores or track your progress unless you Register and Log In

Strength Rating for Blocking Systems

The working load limit of all components used to block cargo from forward movement must be 50% (or more) of the weight of the article being blocked.

The most important securement task is to prevent an article from moving forward, and the best way to prevent forward movement is to immobilize the cargo.

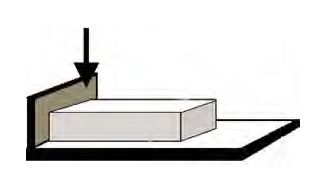

This can be done by placing it against a headboard, bulkhead, stakes or other vehicle structure, or against other cargo that is immobilized in that manner. Blocking and bracing can be placed between the article and vehicle structure, other cargo, or a void-filler.

A “void-filler” is material used to fill a space between articles of cargo and the structure of the vehicle, that has sufficient strength to prevent movement of the articles of cargo (for example, 4 ft. x 4 ft. timbers placed between two adjacent articles of cargo to fill the void).

A direct tiedown can also be used to secure cargo against forward movement.

Securement System Strength Rating for Marked Components:

The working load limit of a tiedown is the working load limit of its weakest part, including anchor points (that is, a tiedown is only as strong as its weakest link). In the case of synthetic webbing, the working load limit is the working load limit of the tiedown assembly or the anchor point, whichever is the least.

Some manufacturers mark their manufactured tiedown assemblies, or components, with a numeric Working Load Limit value. In the absence of other information, this value should be used as the working load limit of the component or assembly.

Other manufacturers mark components using a code or symbol that is defined in a recognized standard. For example, a piece of grade 7 chain may be marked with a 7 or 70, in accordance with the standard of the National Association of Chain Manufacturers. The standard then gives the Working Load Limit for that piece of chain, depending on its size.

Securement System Strength Rating for Unmarked Components:

Securement components and assemblies which are not marked are considered to have working load limits as specified in the Working Load Limit Table

Note: If markings cannot be read, the tiedown will be considered unmarked.

Carriers should try to purchase and use components that are rated and marked by their manufacturer. That way, the carrier, driver, shipper and inspector can all verify that the proper equipment is being used for the job.

Note: Friction mats provide a resistance to horizontal movement equal to 50% of the cargo weight that is resting on the mat.

Cargo Placement and Restraint:

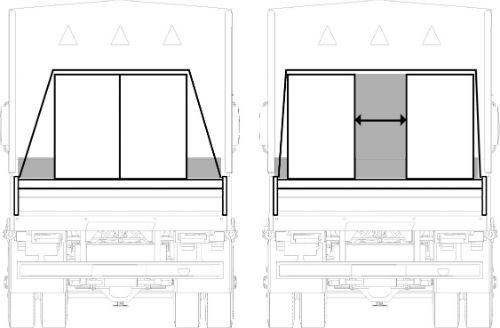

Articles of cargo that are placed beside each other and secured by side-to-side, indirect tiedowns must be either:

- Placed in direct contact with each other, or

- Prevented from shifting towards each other.

Some tiedowns lose their initial tension very quickly in normal driving if there are gaps between articles. Articles must be placed in contact with each other to ensure that there are no gaps, or must be secured by some means to prevent them from moving towards each other in transit.

This requirement applies to all layers and stacks of articles that are loaded across a vehicle.

Where two or more long articles (like metal ingots or bundles of reinforcing bars) are loaded lengthwise on a vehicle, if the space between articles cannot be filled with other cargo or blocking, transverse tiedowns can be wrapped around each article to immobilize it against side-to-side movement.

Cargo Securement Terms That Truck Drivers Should Know:

Cargo Securement Terms That Truck Drivers Should Know:

-

Wedge:

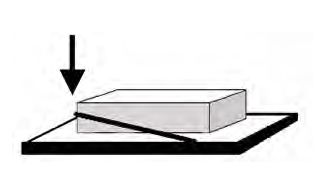

A tapered piece of material, thick at one end and thin at the other, used to help keep cargo from moving.

-

Bracing:

A structure, device, or another substantial article placed against an article to prevent it from tipping that may also prevent it from shifting.

-

Friction mat:

A device placed between the deck of a vehicle and car or between articles of cargo, intended to provide greater friction than exists naturally between these surfaces.

-

Rub Rail:

A rail along the side of a vehicle that protects the side of the vehicle from impacts.

Multiple-Choice Questions:

What is the minimum WLL used to block forward movement of cargo weighing 36,500 lbs?

- 10,000 lbs

- 18,250 lbs

- 36,500 lbs

- 4,500 lbs

The working load limit of all components used to block cargo from forward movement must be 50% (or more) of the weight of the article being blocked.

Blocking is used to:

- Prevent forward movement of cargo.

- Place against or around an article to prevent horizontal movement of the article.

- Provide greater friction between an article and the vehicle.

- Attach a tiedown to.

Blocking:

A structure, device, or another substantial article placed against or around an article to prevent horizontal movement of the article.

By definition, what is a wedge?

- A structure, device, or another substantial article placed against an article to prevent it from tipping that may also prevent it from shifting.

- A short piece of material, usually wood, nailed to the deck to reinforce blocking.

- A tapered piece of material, thick at one end and thin at the other, used to help keep cargo from moving.

- A vertical barrier across a vehicle to prevent forward movement of cargo.

Wedge:

A tapered piece of material, thick at one end and thin at the other, used to help keep cargo from moving.

A friction mat is used to:

- receive a stake or peg, and may also be used as an anchor point.

- prevent it from tipping that may also prevent it from shifting.

- provide greater friction than exists naturally between these surfaces.

- Attach to a tiedown.

Friction mat:

A device placed between the deck of a vehicle and car or between articles of cargo, intended to provide greater friction than exists naturally between these surfaces.

It is accepted that friction mats provide a resistance to horizontal movement equal to:

- 20% of cargo weight.

- 50% of cargo weight.

- 10,000 lbs.

- 100% of cargo weight.

Note: Friction mats provide a resistance to horizontal movement equal to 50% of the cargo weight that is resting on the mat.

What is a rub rail?

- Part of the structure, fitting, or attachment on a vehicle or cargo to which a tiedown is attached.

- The load carrying area of a truck, trailer, or intermodal container.

- A structure, device, or another substantial article placed against or around an article to prevent horizontal movement of the article.

- A rail along the side of a vehicle that protects the side of the vehicle from impacts.

Rub Rail:

A rail along the side of a vehicle that protects the side of the vehicle from impacts.

What is aggregate working load limit?

- The summation of 50% of the working load limits or restraining capacity of all devices used to secure an article on a vehicle.

- The summation of the working load limits or restraining capacity of all devices used to secure an article on a vehicle.

- 50% of the maximum load that may be applied to a component of a cargo securement system during normal service, usually assigned by the manufacturer of the component.

- The maximum load that may be applied to a component of a cargo securement system during normal service, usually assigned by the manufacturer of the component.

Aggregate Working Load Limit:

The summation of the working load limits or restraining capacity of all devices used to secure an article on a vehicle.

A vertical barrier across the front of the deck of a vehicle to prevent forward movement of cargo is a:

- Headboard.

- Deck.

- Rub rail.

- Cab shield.

Headboard:

A vertical barrier across the front of the deck of a vehicle to prevent forward movement of cargo.

In cargo securement, bracing is:

- A structure, device, or another substantial article placed against an article to prevent it from tipping that may also prevent it from shifting.

- A vertical barrier placed directly behind the cab of a tractor to protect the cab in the event cargo should shift forward.

- A rail along the side of a vehicle that protects the side of the vehicle from impacts.

- A strip of material that may be used to unitize articles and is tensioned and clamped or crimped back upon itself. (same as "Strapping")

Bracing:

A structure, device, or another substantial article placed against an article to prevent it from tipping that may also prevent it from shifting.

Complete!

You can Return To The Table Of Contents

TT On Facebook

TT On Facebook