Tips, Tricks, And Techniques For Rookie Drivers

Topic 16099 | Page 11

Forget to mention following distance. Double if not triple maybe even quadruple the following distance. Also, don't get ballzy and try to pass some one. Don't be the person that becomes a crash statistic!

OWI:

Operating While Intoxicated

I didnt see this one so here it is carry multiple different size blocks of wood with you so if a loaded trailer is to low to get under you can save your back Drop your bags back your frame under the trailer set the biggest blocks you can fit on your frame rails raise your bags and jack your trailer you can repeat this till you can get under the trailer Obviously pay attention and use common sense but if youve ever jacked up a 45,000#er than you know its a nightmare specially if its old with crappy cranking gear

Doh! I'll have to remember that little tip!

I didnt see this one so here it is carry multiple different size blocks of wood with you so if a loaded trailer is to low to get under you can save your back Drop your bags back your frame under the trailer set the biggest blocks you can fit on your frame rails raise your bags and jack your trailer you can repeat this till you can get under the trailer Obviously pay attention and use common sense but if youve ever jacked up a 45,000#er than you know its a nightmare specially if its old with crappy cranking gear

Errol, I saw somewhere online to get a piece of galvanized or black steel pipe. A 10 or 12 inch long nipple threaded on both ends. I'm guessing 1 1/4 inch and buy a cap to put on 1 end. Slide it in the hole and the cap keeps it from sliding through. I'm gonna pick one up myself next time I'm home!

Yes!

Galvanized pipe will probably hold up to the trailer banging on it. Thanks for the inspiration!The pin hole is 2". (that's why I mentioned a 2" washer above.) So 1-1/4 or 1-1/2, whichever is available. The length makes it easy to slide in and it'll stay in. Going to Lowes tomorrow!

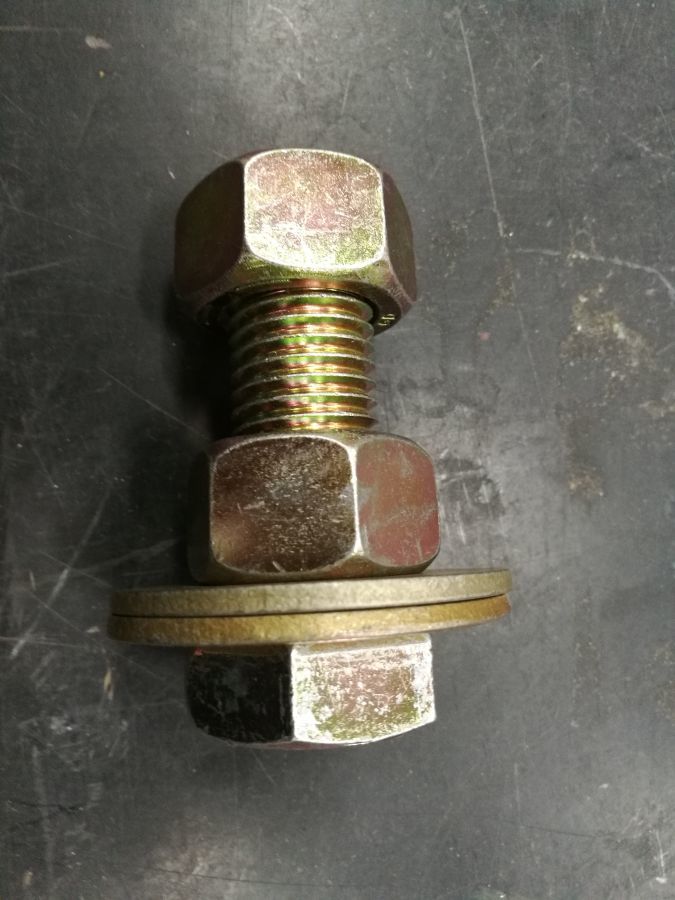

I tried pipe and it crushed. At Tractor Supply I bought one 1" x 3" grade 8 bolt, two 1" grade 8 flat washers and two 1" grade 8 nuts.

I tightened the washers in place with the first nut. (Used wrenches in the store.) The other nut is hand tight. On most of our trailers, the nut will fit through the hole. On the one in the pic the end nut holds it in place.

Sorry... tried several times...

Just can't figure out what this is for! Can't find earlier references.

What is the issue / problem this is trying to solve?

Thanks!

When sliding tandems it helps to have a device that stops you in the correct hole. otherwise you can be there awhile if you need a specific hole. they sell a piece of metal for $25... i boughy several then forgot to remove them lol

Tandems:

Tandem Axles

A set of axles spaced close together, legally defined as more than 40 and less than 96 inches apart by the USDOT. Drivers tend to refer to the tandem axles on their trailer as just "tandems". You might hear a driver say, "I'm 400 pounds overweight on my tandems", referring to his trailer tandems, not his tractor tandems. Tractor tandems are generally just referred to as "drives" which is short for "drive axles".

Tandem:

Tandem Axles

A set of axles spaced close together, legally defined as more than 40 and less than 96 inches apart by the USDOT. Drivers tend to refer to the tandem axles on their trailer as just "tandems". You might hear a driver say, "I'm 400 pounds overweight on my tandems", referring to his trailer tandems, not his tractor tandems. Tractor tandems are generally just referred to as "drives" which is short for "drive axles".

The easiest way to move the tandems to a specific hole is to use a marker on the ground, either in front of or behind the edge of the step on the driver’s side of the cab. I use extra load seals, the fluorescent orange ones Walmart seals outbound store loads with.

If you need to slide the tandems (for instance) 1 foot, or two holes (standard spacing), to move about 800 pounds off the drive axles and onto the tandems, place your marker on the ground 1 foot behind the edge of the step. Move in reverse until the edge if the step is aligned with the mark. Stop, reset the pin and then pull up so the tandems are relocked.

I typically move tandems 3-4 times in a given shift, depending on the work assignment. Dealing with nuts, bolts, bar and other things is time consuming. What I described is the quickest, easiest way to improve accuracy when adjusting the tandems.

Marc this is something your trainer will cover with you and should have you practice and execute in real-time situations.

Tandems:

Tandem Axles

A set of axles spaced close together, legally defined as more than 40 and less than 96 inches apart by the USDOT. Drivers tend to refer to the tandem axles on their trailer as just "tandems". You might hear a driver say, "I'm 400 pounds overweight on my tandems", referring to his trailer tandems, not his tractor tandems. Tractor tandems are generally just referred to as "drives" which is short for "drive axles".

Tandem:

Tandem Axles

A set of axles spaced close together, legally defined as more than 40 and less than 96 inches apart by the USDOT. Drivers tend to refer to the tandem axles on their trailer as just "tandems". You might hear a driver say, "I'm 400 pounds overweight on my tandems", referring to his trailer tandems, not his tractor tandems. Tractor tandems are generally just referred to as "drives" which is short for "drive axles".

Always keep a good back scratcher within arms reach.

This got me in school. Always have spare, fresh batteries available. Your flashlight needs to be BRIGHT for daylight checks.

The easiest way to move the tandems to a specific hole is to use a marker on the ground, either in front of or behind the edge of the step on the driver’s side of the cab. I use extra load seals, the fluorescent orange ones Walmart seals outbound store loads with.

If you need to slide the tandems (for instance) 1 foot, or two holes (standard spacing), to move about 800 pounds off the drive axles and onto the tandems, place your marker on the ground 1 foot behind the edge of the step. Move in reverse until the edge if the step is aligned with the mark. Stop, reset the pin and then pull up so the tandems are relocked.

I typically move tandems 3-4 times in a given shift, depending on the work assignment. Dealing with nuts, bolts, bar and other things is time consuming. What I described is the quickest, easiest way to improve accuracy when adjusting the tandems.

Marc this is something your trainer will cover with you and should have you practice and execute in real-time situations.

Thanks "G".

Yeah... in approx. 400 hrs. (OK... 380ish...) I think we spent about 7 min. on sliding tandems!

License to Learn!

Tandems:

Tandem Axles

A set of axles spaced close together, legally defined as more than 40 and less than 96 inches apart by the USDOT. Drivers tend to refer to the tandem axles on their trailer as just "tandems". You might hear a driver say, "I'm 400 pounds overweight on my tandems", referring to his trailer tandems, not his tractor tandems. Tractor tandems are generally just referred to as "drives" which is short for "drive axles".

Tandem:

Tandem Axles

A set of axles spaced close together, legally defined as more than 40 and less than 96 inches apart by the USDOT. Drivers tend to refer to the tandem axles on their trailer as just "tandems". You might hear a driver say, "I'm 400 pounds overweight on my tandems", referring to his trailer tandems, not his tractor tandems. Tractor tandems are generally just referred to as "drives" which is short for "drive axles".

New Reply:

New! Check out our help videos for a better understanding of our forum features

Preview:

This topic has the following tags:

Advice For New Truck Drivers First Solo Months On The Road Items To Bring On The Road Life On The Road Truck Equipment

TT On Facebook

TT On Facebook

Some wisdom from a noob; so take it with a grain of salt.

Most if not all newer trucks have anti-lock breaks and there is a button on the dash for traction control. Along with the differential interlock can save your butt.

In mountain driving during the winter traction control on the way up and anti-lock on the way down if there is no ice. If there is ice, park! Also, keep engine RPM low will also help from breaking traction (1000-1100 RPM). While going down a snowy pass, slow way down. Press gently on the breaks until you start to feel them grab and hold pressure on the breaks to slow 5 to 10 MPH below your safe speed then rinse and repeat. Sudden stabs on the breaks will cause loss of traction. Remember no sudden control actions! Be gentle and slow!

If there is ice, black ice and/or you need chains, park. No load is worth yours or someone else's life.

There ya go, Dave's winter driving tips for today!