Can I Physically Handle Trucking?

Topic 24125 | Page 3

The walls are not all that strong, And the floor probably flexes. The frame is strong but it is still 53’ long. That is a long chunk of steel to keep rigid, and yet attach wheels, pile on massive weight, and roll it around.

The walls are not all that strong, And the floor probably flexes. The frame is strong but it is still 53’ long. That is a long chunk of steel to keep rigid, and yet attach wheels, pile on massive weight, and roll it around.

Not entirely true.

Unlike a flatbed, a dryvan or reefer does not have a true frame supporting the floor. Structural integrity is achieved by the entire assembly of the roof, side walls, front wall, floor and door frame working as one unit to support the weight of the cargo. If any one of those components fails, it can fold like an accordion. That’s why inspection of side rivets, floor crossmembers and the roof edges is so important.

Dryvan:

A trailer or truck that that requires no special attention, such as refrigeration, that hauls regular palletted, boxed, or floor-loaded freight. The most common type of trailer in trucking.Reefer:

A refrigerated trailer.

HOS:

Hours Of Service

HOS refers to the logbook hours of service regulations.

The walls are not all that strong, And the floor probably flexes. The frame is strong but it is still 53’ long. That is a long chunk of steel to keep rigid, and yet attach wheels, pile on massive weight, and roll it around.

Not entirely true.

Unlike a flatbed, a dryvan or reefer does not have a true frame supporting the floor. Structural integrity is achieved by the entire assembly of the roof, side walls, front wall, floor and door frame working as one unit to support the weight of the cargo. If any one of those components fails, it can fold like an accordion. That’s why inspection of side rivets, floor crossmembers and the roof edges is so important.

You are correct. Obviously. :)

I’ve been crawling under one for two days now and it didn’t even occur to me until you said that that the frame the tandems are on does not extend to the front. Which means it most likely flexes quite a bit.

And yes, once it is breached anywhere, it is subject to complete failure. Which is why they use airbags to flip them back up. The wall uprights are thin metal (steel or aluminum? I’m not sure which) with a thin aluminum skin covering them.

Which brings up something I thought of on pretrip. The apron is steel, and the band around the bottom (not sure what it is called) is aluminum. And I think the uprights of the walls are steel, covered with aluminum.

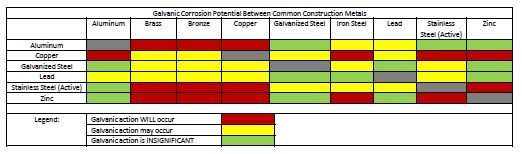

How does the dissimilar metals not cause corrosion?

Tandems:

Tandem Axles

A set of axles spaced close together, legally defined as more than 40 and less than 96 inches apart by the USDOT. Drivers tend to refer to the tandem axles on their trailer as just "tandems". You might hear a driver say, "I'm 400 pounds overweight on my tandems", referring to his trailer tandems, not his tractor tandems. Tractor tandems are generally just referred to as "drives" which is short for "drive axles".

Tandem:

Tandem Axles

A set of axles spaced close together, legally defined as more than 40 and less than 96 inches apart by the USDOT. Drivers tend to refer to the tandem axles on their trailer as just "tandems". You might hear a driver say, "I'm 400 pounds overweight on my tandems", referring to his trailer tandems, not his tractor tandems. Tractor tandems are generally just referred to as "drives" which is short for "drive axles".

Dryvan:

A trailer or truck that that requires no special attention, such as refrigeration, that hauls regular palletted, boxed, or floor-loaded freight. The most common type of trailer in trucking.Reefer:

A refrigerated trailer.

HOS:

Hours Of Service

HOS refers to the logbook hours of service regulations.

The roof attached to the sidewalls...actually creates floor strength...similar to a truss bridge.

Overall there are very few steel parts; slide rails, kingpin, apron (aka upper coupler), subframe (aka tandem assembly), door frame, crash wall on the front (the band you mentioned), door latch bars, and landing gear. That’s the major stuff.

Tandem:

Tandem Axles

A set of axles spaced close together, legally defined as more than 40 and less than 96 inches apart by the USDOT. Drivers tend to refer to the tandem axles on their trailer as just "tandems". You might hear a driver say, "I'm 400 pounds overweight on my tandems", referring to his trailer tandems, not his tractor tandems. Tractor tandems are generally just referred to as "drives" which is short for "drive axles".

The roof attached to the sidewalls...actually creates floor strength...similar to a truss bridge.

Overall there are very few steel parts; slide rails, kingpin, apron (aka upper coupler), subframe (aka tandem assembly), door frame, crash wall on the front (the band you mentioned), door latch bars, and landing gear. That’s the major stuff.

Perfect explanation. Textbook.

Tandem:

Tandem Axles

A set of axles spaced close together, legally defined as more than 40 and less than 96 inches apart by the USDOT. Drivers tend to refer to the tandem axles on their trailer as just "tandems". You might hear a driver say, "I'm 400 pounds overweight on my tandems", referring to his trailer tandems, not his tractor tandems. Tractor tandems are generally just referred to as "drives" which is short for "drive axles".

And I found the answer to the corrosion question. Galvanized steel and aluminum has an insignificant amount of galvanic activity, which causes corrosion

And I found the answer to the corrosion question. Galvanized steel and aluminum has an insignificant amount of galvanic activity, which causes corrosion

Forgot the chart.

And I found the answer to the corrosion question. Galvanized steel and aluminum has an insignificant amount of galvanic activity, which causes corrosion

Thanks. Interesting, makes sense. Chemistry was never my thing...mfg.-engineering, “yes”.

I had the fortune of being involved in two WIP shop floor software projects for Strick Trailer ovrr 20 years ago. Once completed I had most of the assembly process burned into my firmware.

Here is a really good you tube video on trailer assembly:

https://m.youtube.com/watch?v=Vz6ejxYZ1b0

And I found the answer to the corrosion question. Galvanized steel and aluminum has an insignificant amount of galvanic activity, which causes corrosion

Thanks. Interesting, makes sense. Chemistry was never my thing...mfg.-engineering, “yes”.

I had the fortune of being involved in two WIP shop floor software projects for Strick Trailer ovrr 20 years ago. Once completed I had most of the assembly process burned into my firmware.

Here is a really good you tube video on trailer assembly:

https://m.youtube.com/watch?v=Vz6ejxYZ1b0

Chemistry? Me either, my info came from working on aircraft. We had to be very careful with fasteners used on aluminum aircraft. We had to use stainless steel. Although looking at the chart, the brass screws we had to use near compass parts should have been an issue.

Thanks for the video, I'll watch that while I get ready for school.

New Reply:

New! Check out our help videos for a better understanding of our forum features

Preview:

This topic has the following tags:

DOT Physical Health Concerns Life On The Road Trailers Truck Driving Lifestyle Women In Trucking

TT On Facebook

TT On Facebook

Swing doors closed and fully secured are required for total, uncompromised structural integrity.

On a roll up door trailer, the “beefier” door frame all-by-itself provides the necessary integrity. Trade-off, it’s much heavier.