Pre-Trip Inspection - My Way! A Must See!

Topic 3798 | Page 1

Engine Compartment

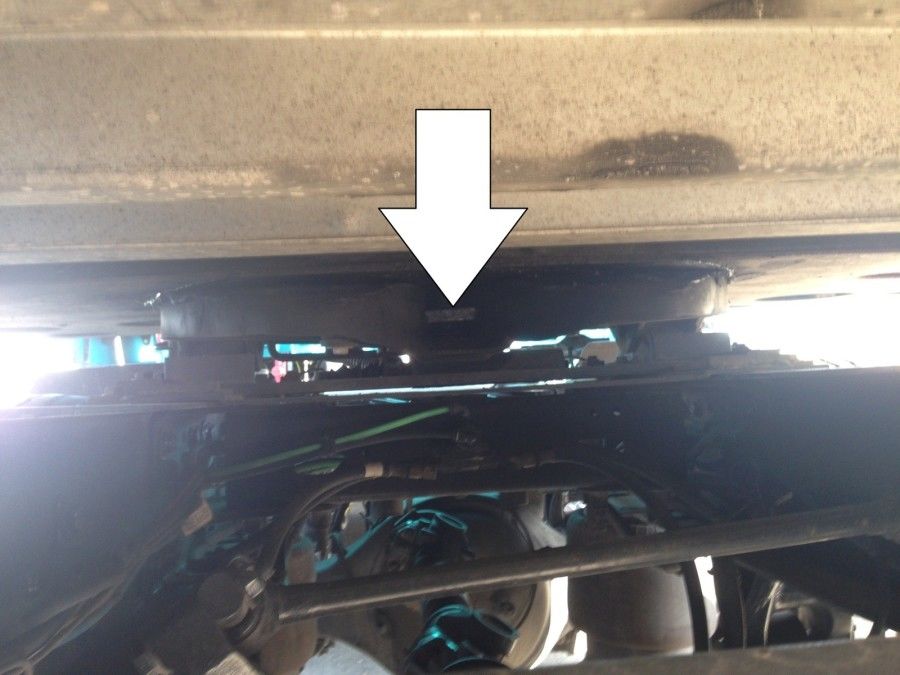

Leaks-

Check for leaks under the truck.

Daniel's Tip: This is easy to forget, I suggest you mention it first to get it out of the way.

Belt Driven Alternator-

Belt Driven Alternator-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. All wires connected The belt is not cracked or frayed and the free play on the belt is between 1/2 to 3/4 of an inch.

Daniel's Tip: Remember the Alternator is Belt Driven. Do not forget to mention the belt!

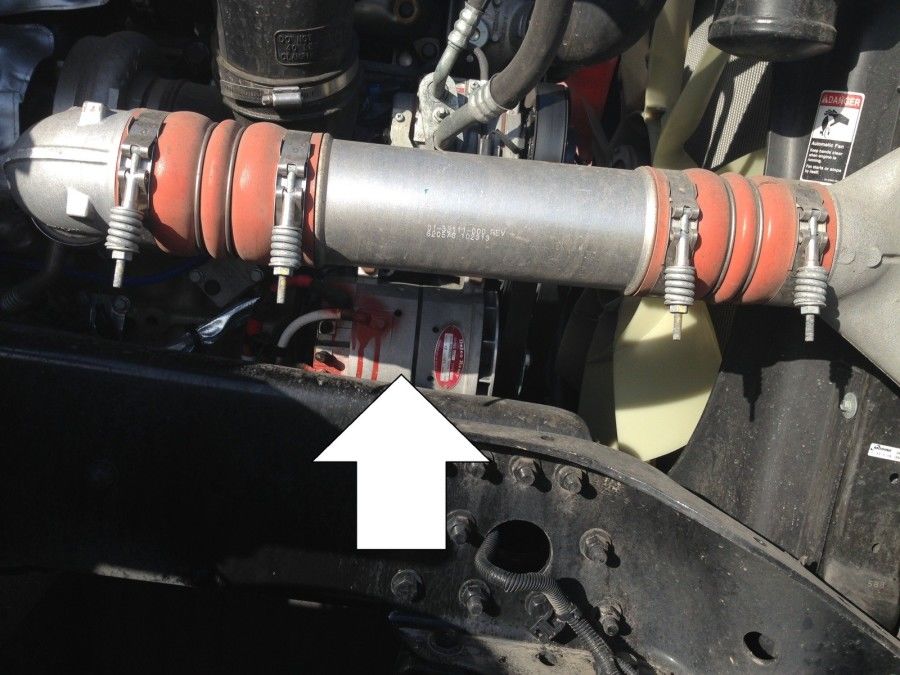

General Hoses Passenger Side-

General Hoses Passenger Side-

Properly Mounted and Secure at both ends. No Abrasions, Bulges or Cuts and not leaking.

Daniel's Tip: Don't forget to mention "at both ends". Fluids run through these hoses so you must say that they're not leaking.

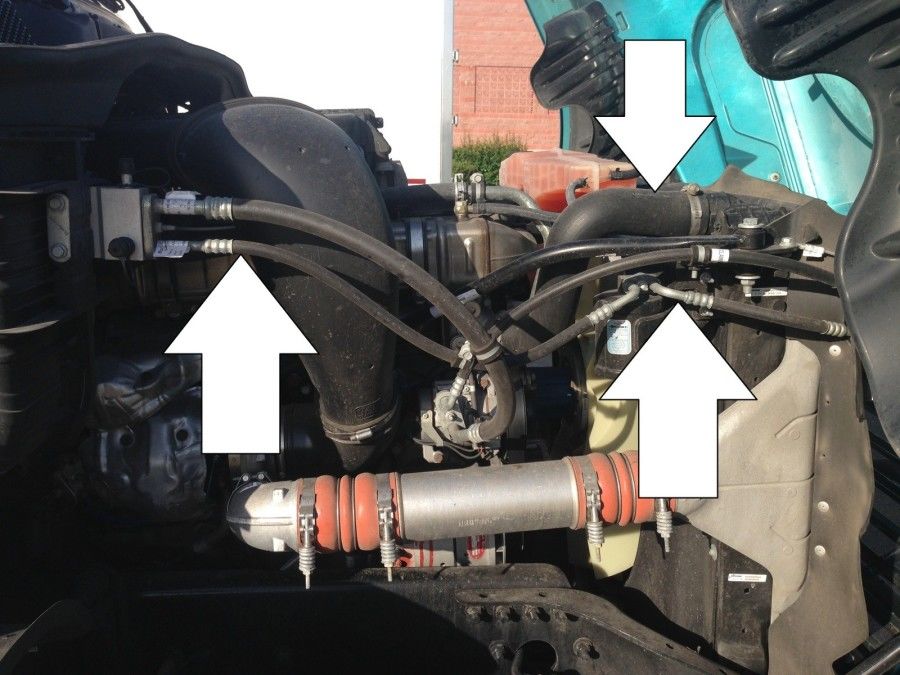

General Hoses Drivers Side-

General Hoses Drivers Side-

Properly Mounted and Secure at both ends. No Abrasions, Bulges or Cuts and not leaking.

Daniel's Tip: Same thing - Don't forget to mention "at both ends". Fluids run through these hoses so you must say that they're not leaking.

Coolant Reservoir-

Coolant Reservoir-

Properly Mounted and Secure Not Cracked, Bent, or Broken. Not leaking. Not leaking and filled to manufactures specifications.

Daniel's Tip: The Reservoir must be Properly Mounted and Secure, but don't forget about the hoses leading to and from the Reservoir! You must also state that its filled to manufactures specifications and not leaking.

Belt Driven Water Pump-

Belt Driven Water Pump-

Properly Mounted and Secure Not Cracked, Bent, or Broken. Not leaking The belt is not cracked or frayed and the free play on the belt is between 1/2 to 3/4 of an inch.

Daniel's Tip: The Water Pump is Belt Driven, don't forget that belt! Check all the hoses running to and from the Water Pump, ensure that nothing is leaking.

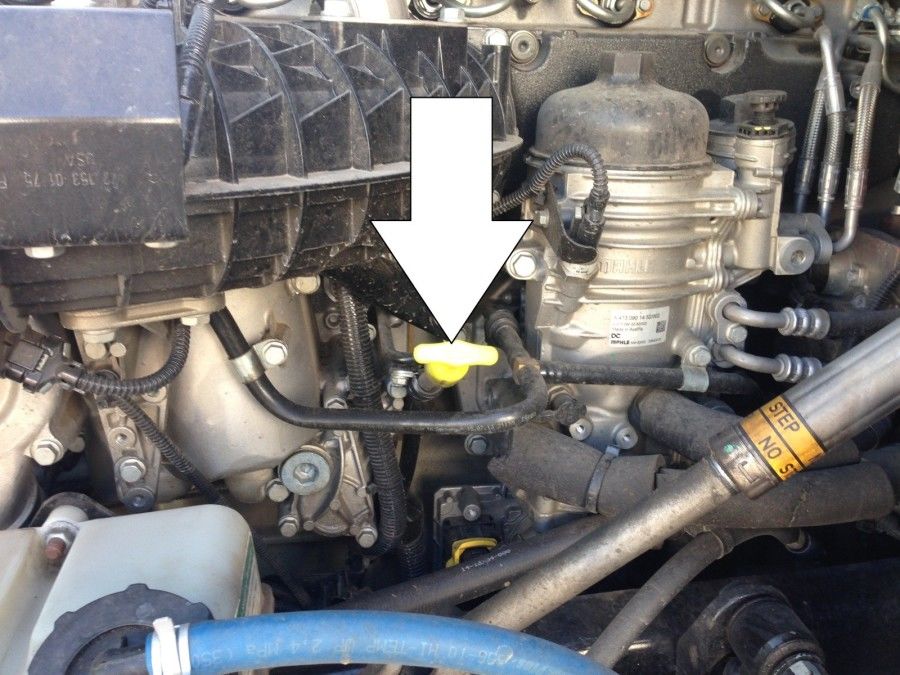

Oil Level-

Oil Level-

Filled to manufactures specifications.

Daniel's Tip: You don't need to take out the dipstick. Just point at the dipstick and say its filled to manufactures specifications.

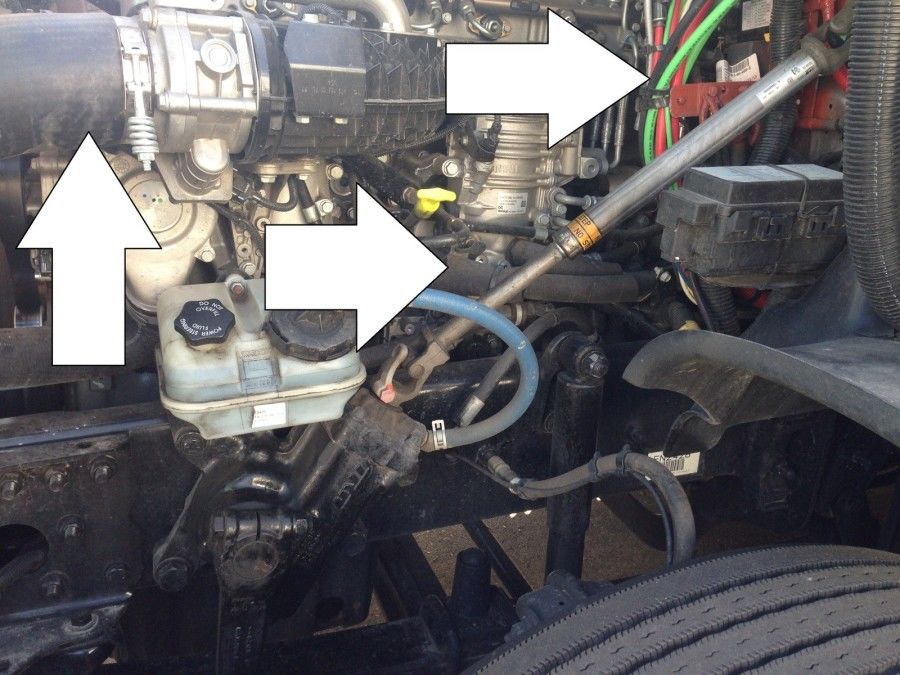

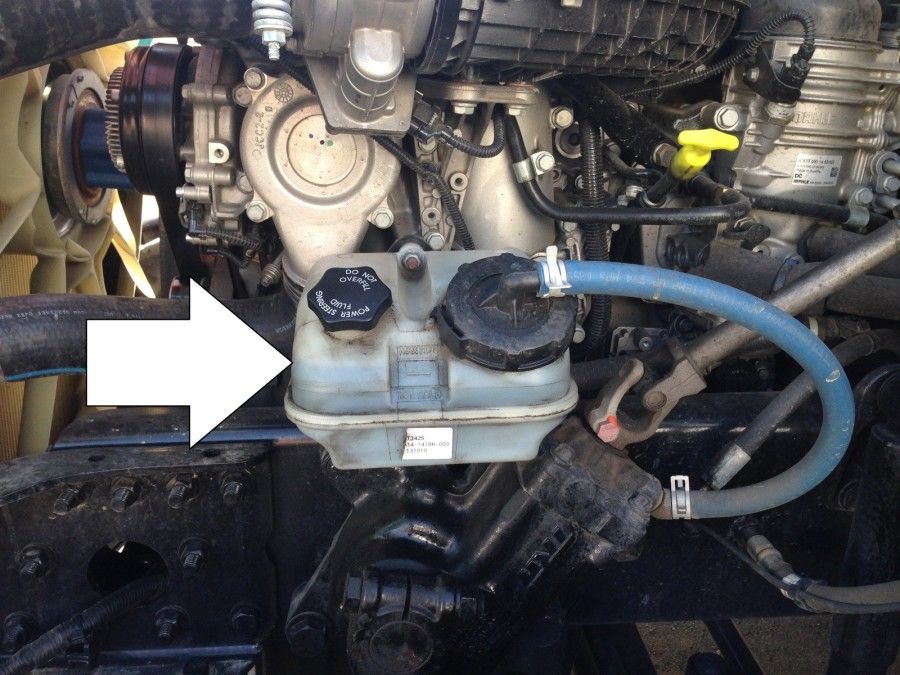

Power Steering Fluid Reservoir-

Power Steering Fluid Reservoir-

Properly Mounted and Secure Not Cracked, Bent, or Broken. Not leaking and filled to manufactures specifications.

Daniel's Tip: We've got many hoses here. Don't abandon those hoses! Ensure nothing is leaking and filled to manufactures specifications.

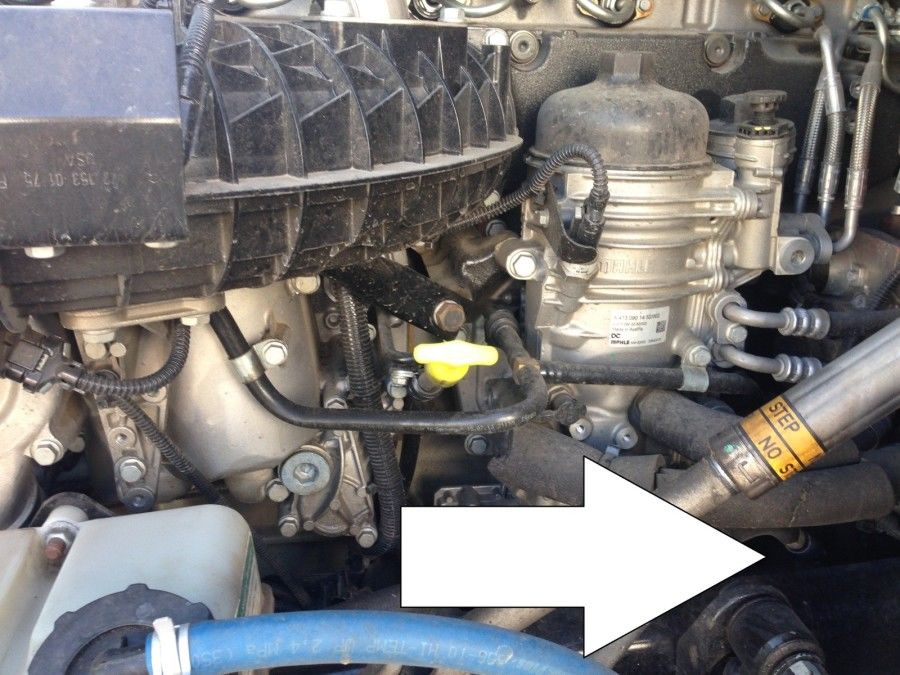

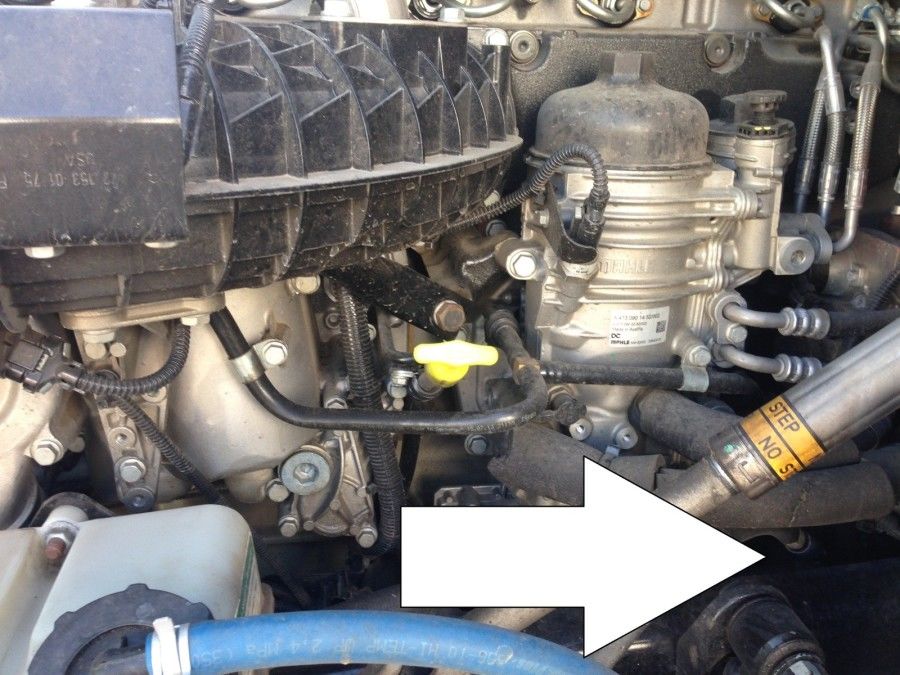

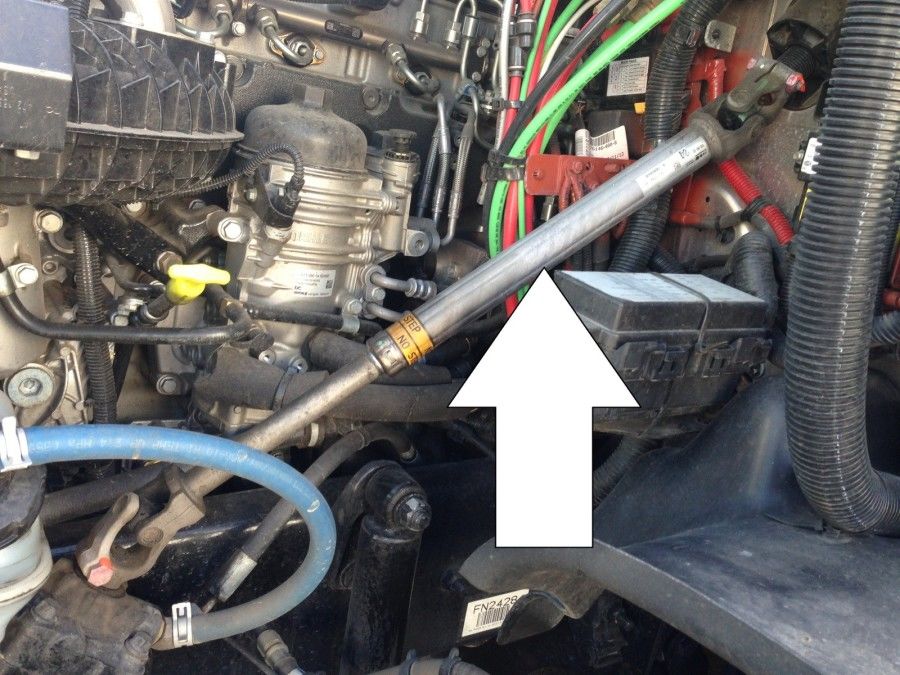

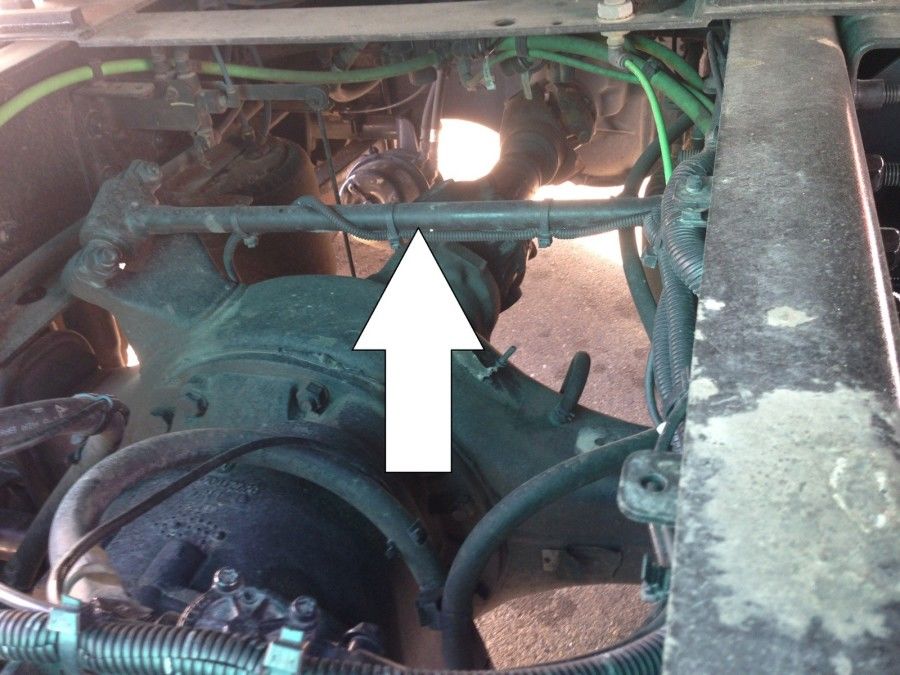

Gear Driven Air Compressor-

Gear Driven Air Compressor-

Properly Mounted and Secure Not Cracked, Bent, or Broken. Not leaking

Daniel's Tip: The Air Compressor is Gear Driven. It is located behind the Frame and you really cannot see it. As long as you state all the above and point in the general area you'll be fine.

Gear Driven Power Steering Pump-

Gear Driven Power Steering Pump-

Properly Mounted and Secure Not Cracked, Bent, or Broken. Not leaking

Daniel's Tip: Likewise, the Power Steering Pump is located at the same place as the Air Compressor. This is also Gear Driven. Ensure its not leaking and state the above - point in the general area and you're good.

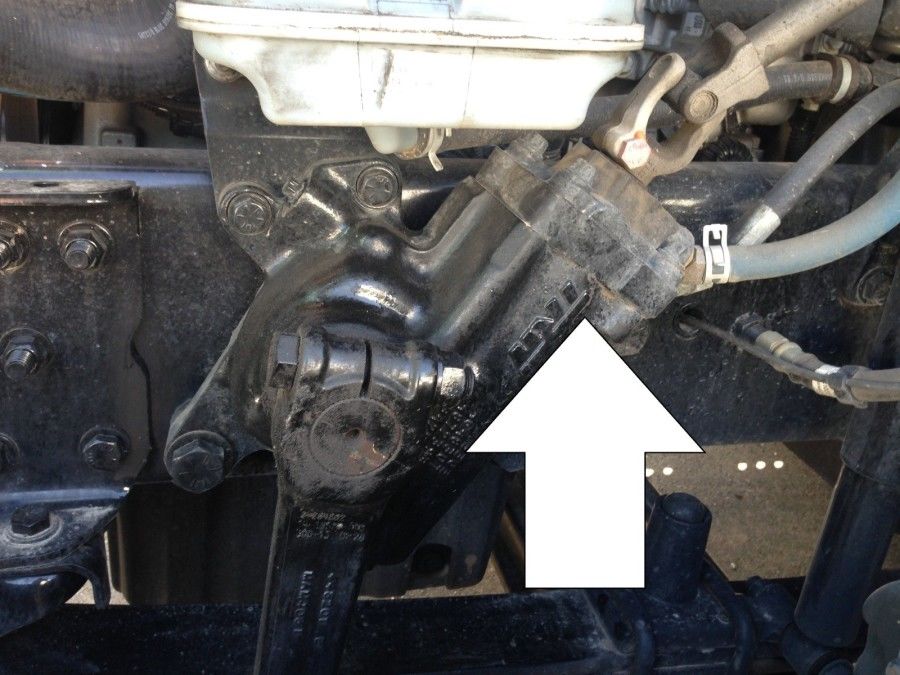

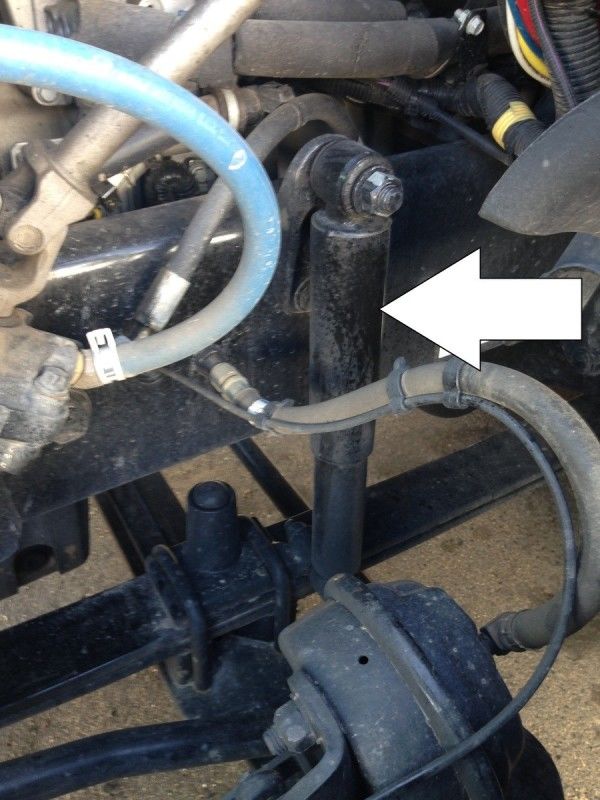

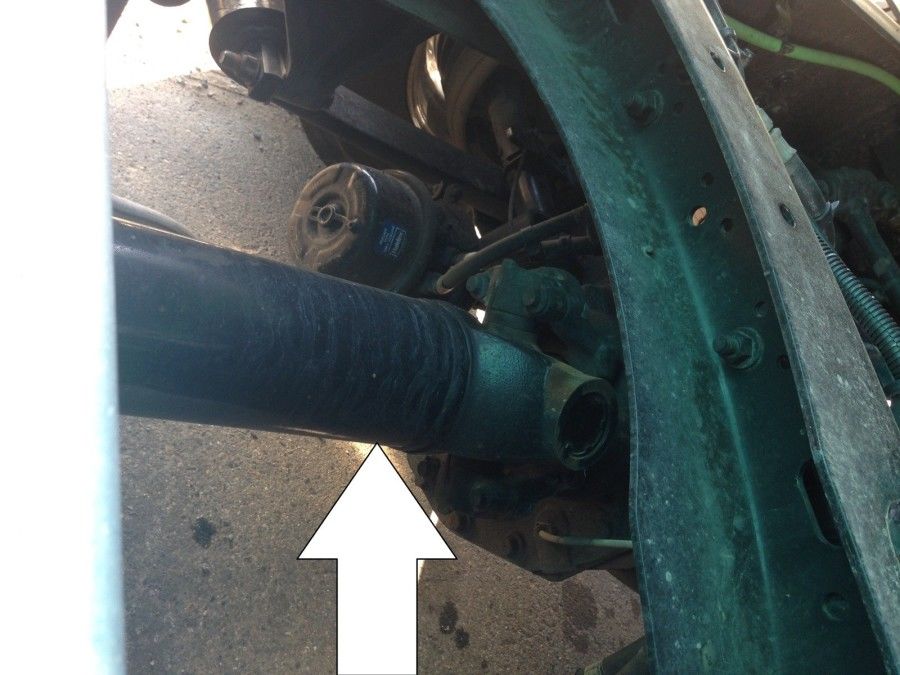

Gear Box and Hoses-

Gear Box and Hoses-

Properly Mounted and Secure Not Cracked, Bent, or Broken. No Abrasions, Bulges or Cuts and not leaking

Daniel's Tip: Don't forget to mention the hoses and not leaking.

Steering Column-

Steering Column-

Properly Mounted and Secure Not Cracked, Bent, or Broken.

Daniel's Tip: Combine the Pitman Arm, Drag Link, Tie Rod, Castle Nuts and Cotter Pins and state that you'll be checking all of these the same way. Point at each item and name the part, then state "I check all of these the same way, they're all to be Properly Mounted and Secure and not Cracked, Bent, or Broken. While pointing at the Castle Nuts and Cotter Pins don't forget to state that there are no Missing Castle Nuts or Cotter Pins. All of these items make up your Steering Linkage.

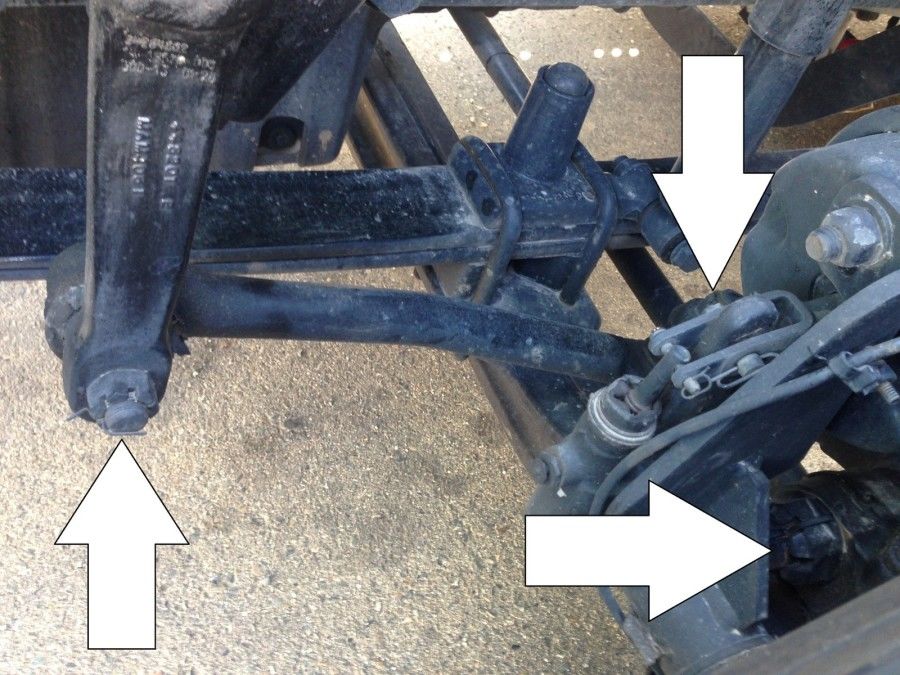

Pitman Arm-

Pitman Arm-

Properly Mounted and Secure Not Cracked, Bent, or Broken.

Daniel's Tip: Combine the Pitman Arm, Drag Link, Tie Rod, Castle Nuts and Cotter Pins and state that you'll be checking all of these the same way. Point at each item and name the part, then state "I check all of these the same way, they're all to be Properly Mounted and Secure and not Cracked, Bent, or Broken. While pointing at the Castle Nuts and Cotter Pins don't forget to state that there are no Missing Castle Nuts or Cotter Pins. All of these items make up your Steering Linkage.

HOS:

Hours Of Service

HOS refers to the logbook hours of service regulations.Drag Link-

Properly Mounted and Secure. Not Cracked, Bent, or Broken.

Daniel's Tip: Combine the Pitman Arm, Drag Link, Tie Rod, Castle Nuts and Cotter Pins and state that you'll be checking all of these the same way. Point at each item and name the part, then state "I check all of these the same way, they're all to be Properly Mounted and Secure and not Cracked, Bent, or Broken. While pointing at the Castle Nuts and Cotter Pins don't forget to state that there are no Missing Castle Nuts or Cotter Pins. All of these items make up your Steering Linkage.

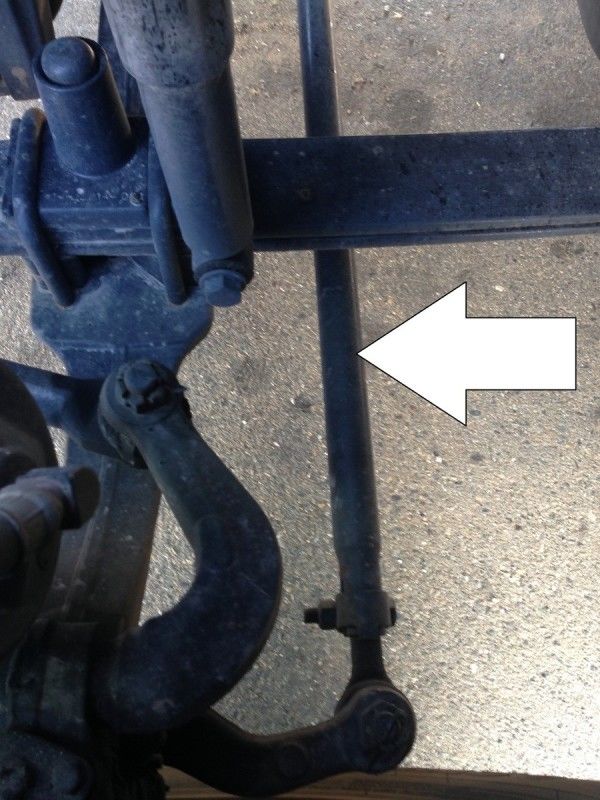

Tie Rod-

Tie Rod-

Properly Mounted and Secure. Not Cracked, Bent, or Broken.

Daniel's Tip: Combine the Pitman Arm, Drag Link, Tie Rod, Castle Nuts and Cotter Pins and state that you'll be checking all of these the same way. Point at each item and name the part, then state "I check all of these the same way, they're all to be Properly Mounted and Secure and not Cracked, Bent, or Broken. While pointing at the Castle Nuts and Cotter Pins don't forget to state that there are no Missing Castle Nuts or Cotter Pins. All of these items make up your Steering Linkage.

Caste Nuts and Cotter Pins-

None missing. Cotter Pin is present.

Daniel's Tip: Lot's of folks like to combine this with the Drag Link. I do not, I like to say this separely at the very end of my Steering Section. As long as you say there are none missing and the Cotter Pin is present you'll be good to go! Don't forget that there are three Castle Nuts and you must point at all three.

Spring Hanger-

Spring Hanger-

Properly Mounted and Secure at both front and rear. Not Cracked, Bent, or Broken.

Daniel's Tip: The difference between a Hanger and a Mount is that Hangers are much, much smaller. I could go technical but don't over complicate this. The Hangers are in the front, Mounts in the back. Be sure to say "at both front and rear".

Leaf Springs-

Leaf Springs-

Properly Mounted and Secure at both ends. Not Cracked, Bent, or Broken. None are shifted.

Daniel's Tip: Leaf Springs will always be in the Engine Compartment, they're not Spring Arms! Don't let any fool tell you that because they would be wrong. These are Leaf Springs because there are multiple Springs - plural. Be sure to say none are shifted.

U-Bolts-

U-Bolts-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. None missing.

Daniel's Tip: Very simple item. Just be sure to say none are missing, that line is easily forgettable.

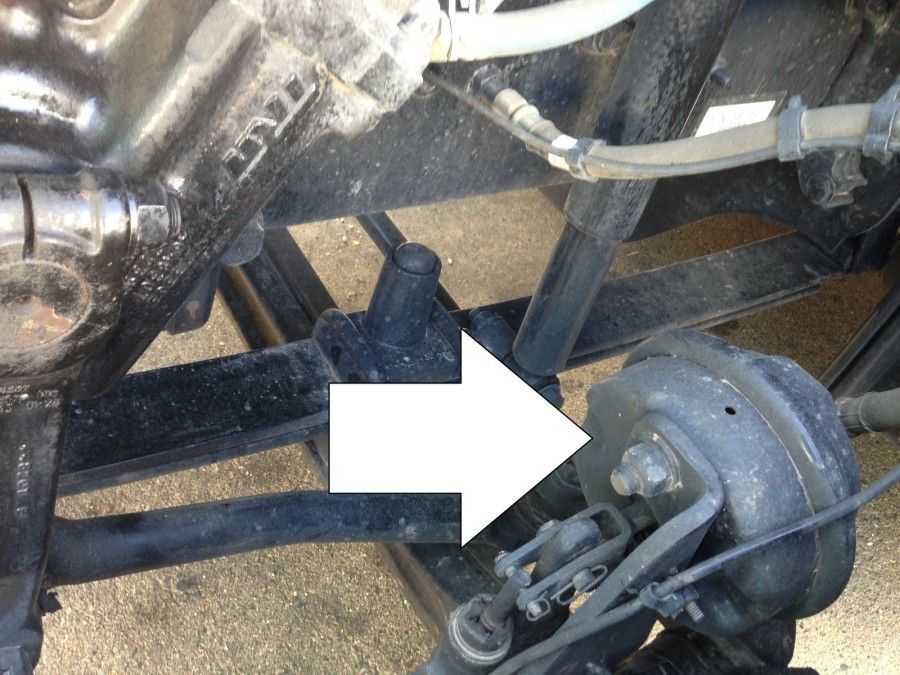

Shock Absorber-

Shock Absorber-

Properly Mounted and Secure at both ends. Not Cracked, Bent, or Broken. Not leaking.

Daniel's Tip: Don't forget to say "at both ends" and "not leaking". If it'll leak, it'll leak at the point where the top and bottom portion of the Shock meet - in the Middle.

Brake Hose-

Brake Hose-

Properly Mounted and Secure at both ends. No Abrasions, Bulges or Cuts. Not leaking air.

Daniel's Tip: Again, don't forgot to say "at both ends". The Hose is rubber so give it the ABC and not leaking air. You could combine the line with the Chamber but I prefer not to but its very easy to forget to mention the hose. When you're under pressure, you tend to forget the small things - like a hose.

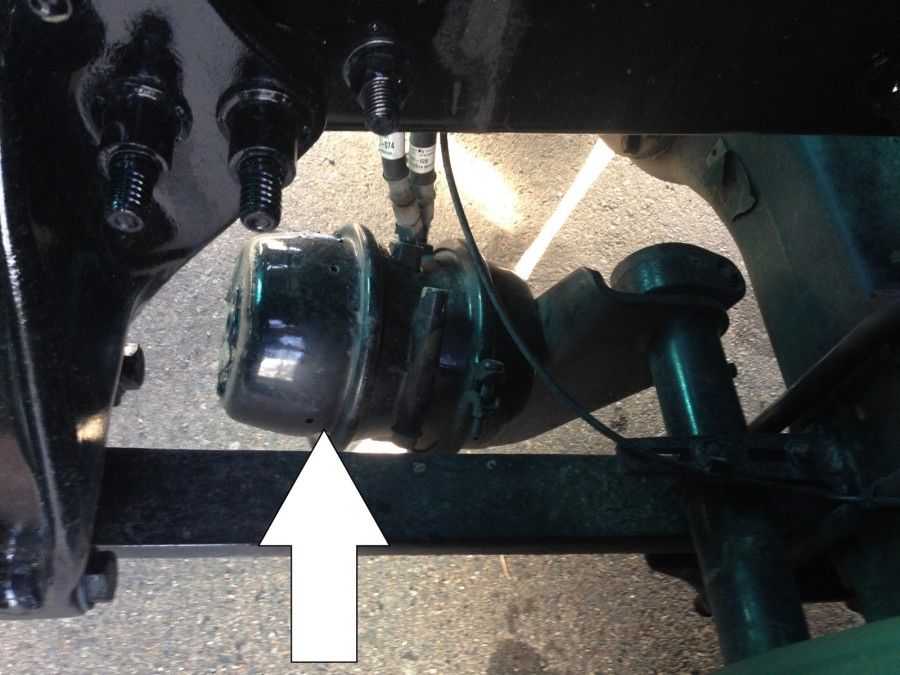

Brake Chamber-

Brake Chamber-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. Not leaking air.

Daniel's Tip: Easy item to inspect, don't forget to mention that it's not leaking air.

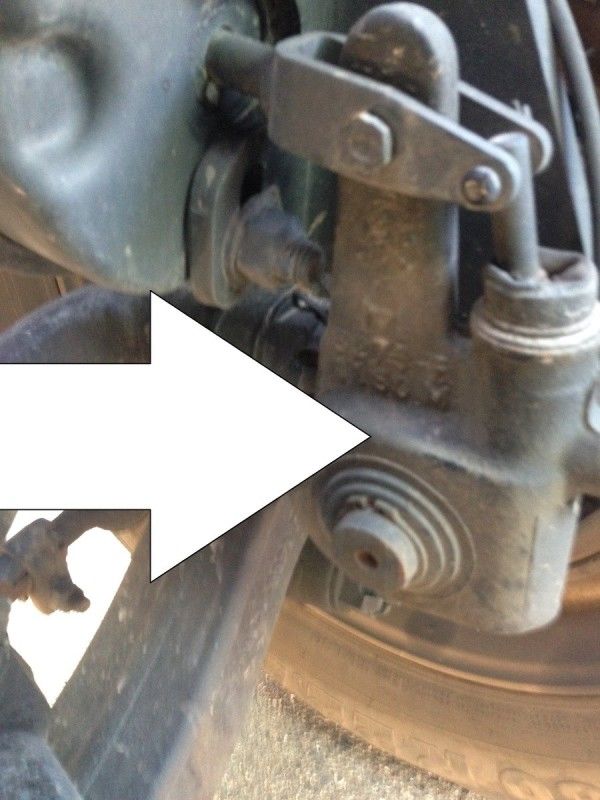

Slack Adjuster and Push Rod-

Slack Adjuster and Push Rod-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. With the brakes released and pulled by hand, the Push Rod should not move more than 1 inch.

Daniel's Tip: The Slack Adjuster and Push Rod are always combined. Please, be very careful with your words on this one. Say it exactly how I wrote it! Memorize that line.

HOS:

Hours Of Service

HOS refers to the logbook hours of service regulations.Brake Drum-

Properly Mounted and Secure. Not Cracked, Bent, or Broken.

Daniel's Tip: Easy item to inspect. Just a simple PMS and CBB.

Brake Lining-

Brake Lining-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. No oil or debris. Friction Material is not worn dangerously thin.

Daniel's Tip: Remember, you're checking for oil or debris and for friction material on the Lining not on the Drum. People often mix this up. You must point exactly at the Brake Lining, like I have it in the picture.

Rim-

Rim-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. No unauthorized welds.

Daniel's Tip: Fairly simple item. Be sure to mention that there cannot be any unauthorized welds.

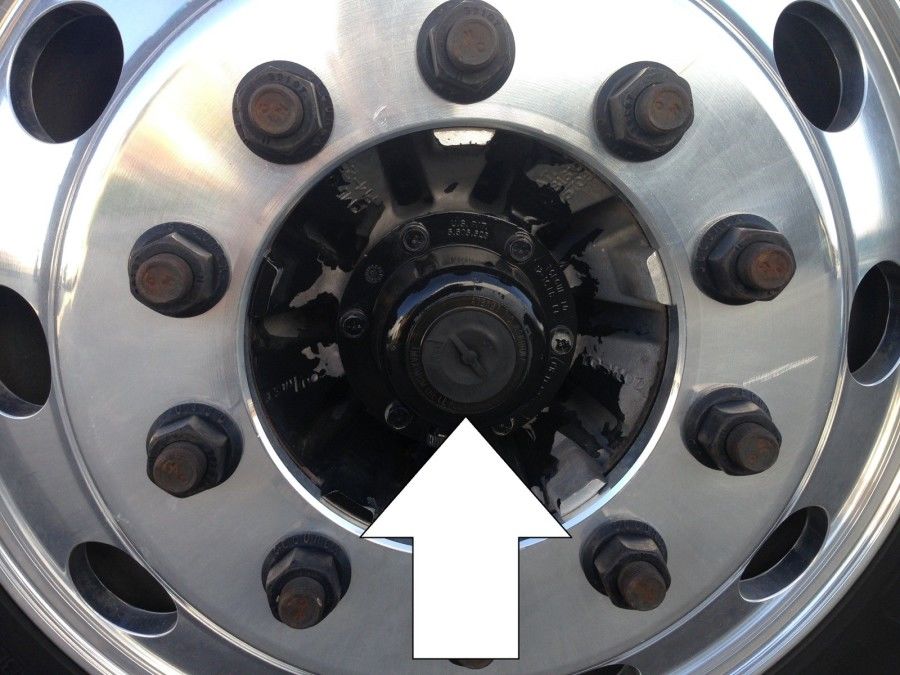

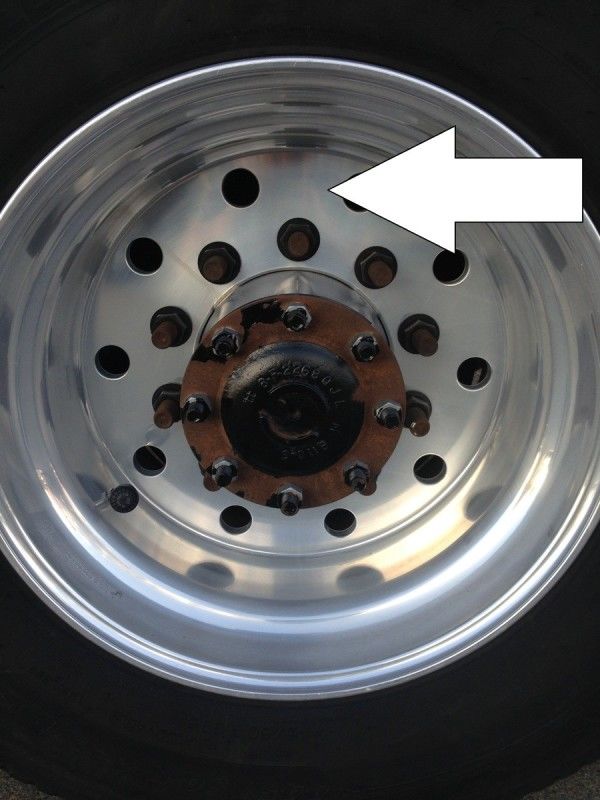

Lug Nuts-

Lug Nuts-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. There are none missing. No rust trails or powder residue. No cracks around the bolt holes.

Daniel's Tip: Rust trails could indicate loose bolts while powder residue and cracks around the bolts holes could be an indication of the bolts being over-tightened. Be sure to let the examiner know you're looking for rust trails or powder residue and no cracks around the bolt holes.

Hub Seal-

Hub Seal-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. Not leaking and filled to manufactures specifications.

Daniel's Tip: My method is that the Hub Seal is located on the Steer Axle, Axle Seal belongs on all the other Axles. Though it doesn't matter if you call the Trailer Axle a Hub Seal. You can call these Hub or Axle Seals. Just be sure to say that its filled to manufactures specifications.

Steer Tire-

Steer Tire-

No Abrasions, Bulges or Cuts to the tread or sidewalls. Tread depth is no less than 4/32 of an inch. Properly filled to manufactures specifications. Check it with an air gauge.

Daniel's Tip: Tires are a big deal! Be sure to look for Abrasions, Buldges or Cuts to the Tread and Sidewalls. Be sure to say it too. Steer tires cannot be less than 4/32 of an inch depth. You must say "of an inch", simply saying "4/32" is not enough. Properly filled to manufactures specifications and you absolutely must add that you check it with an air gauge! You don't have to physically check it with an air gauge on your exam, just mention that you would.

OOS:

When a violation by either a driver or company is confirmed, an out-of-service order removes either the driver or the vehicle from the roadway until the violation is corrected.

Drivers Door Fuel Area

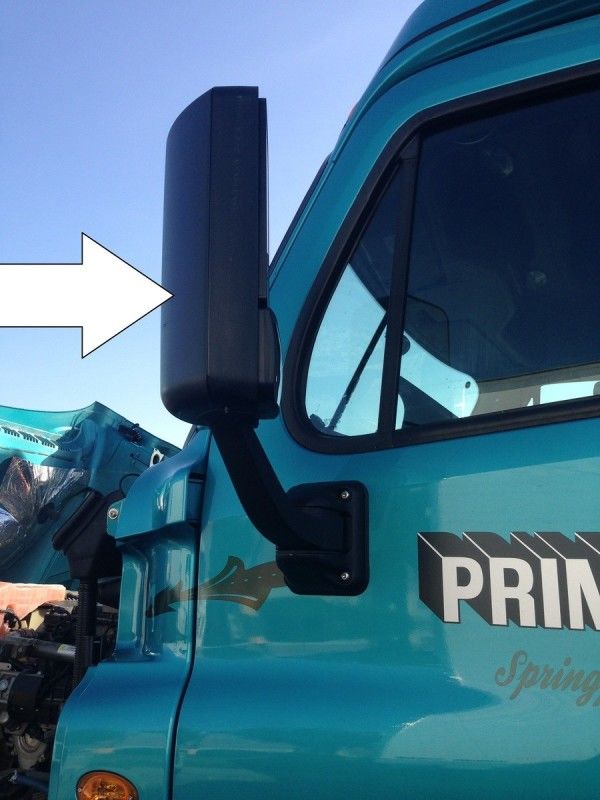

Mirrors-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. and clean.

Daniel's Tip: Be sure to say that it is clean. On your In-Cab you must do the Mirrors all over again the same way, except you'll add that its properly adjusted.

Door and Hinges-

Door and Hinges-

Properly Mounted and Secure. Not Not Cracked, Bent, or Broken. Opens and closes and latches properly. Door seals not worn, torn, or dry rotten.

Daniel's Tip: Physically open the door and point out the Door Seals. Open and close the door several times to demonstrate that the door opens and closes and latches properly.

Fuel Tank-

Fuel Tank-

Properly Mounted and Secure. Not Not Cracked, Bent, or Broken. Not leaking from the tank and cap, cap is on tight.

Daniel's Tip: Be sure to say that it cannot be leaking from the Tank or Cap.

Exhaust System-

Exhaust System-

Properly Mounted and Secure. Not Not Cracked, Bent, or Broken. There are no signs of leaks.

Daniel's Tip: Easy to miss because its not always in sight. Be sure to knock this out quickly to get it out of the way. Remember to look for no signs of leaks.

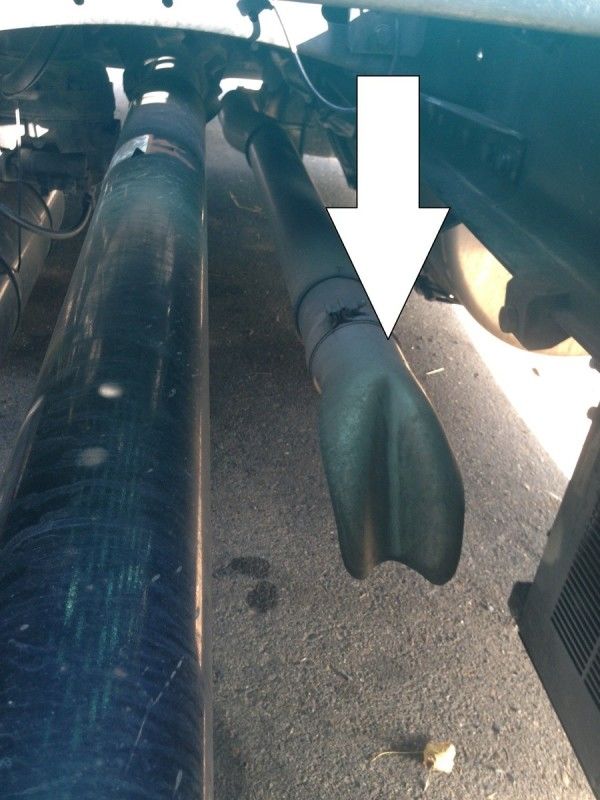

Drive Shaft-

Drive Shaft-

Properly Mounted and Secure. Not Not Cracked, Bent, or Broken. Not twisted, and the U-joints are free of any debris.

Daniel's Tip: I like to knock out the Drive Shaft after the Exhaust just because its right next to it. No reason to skip around. Be sure to state that its not twisted and the U-Joints are free of any debris.

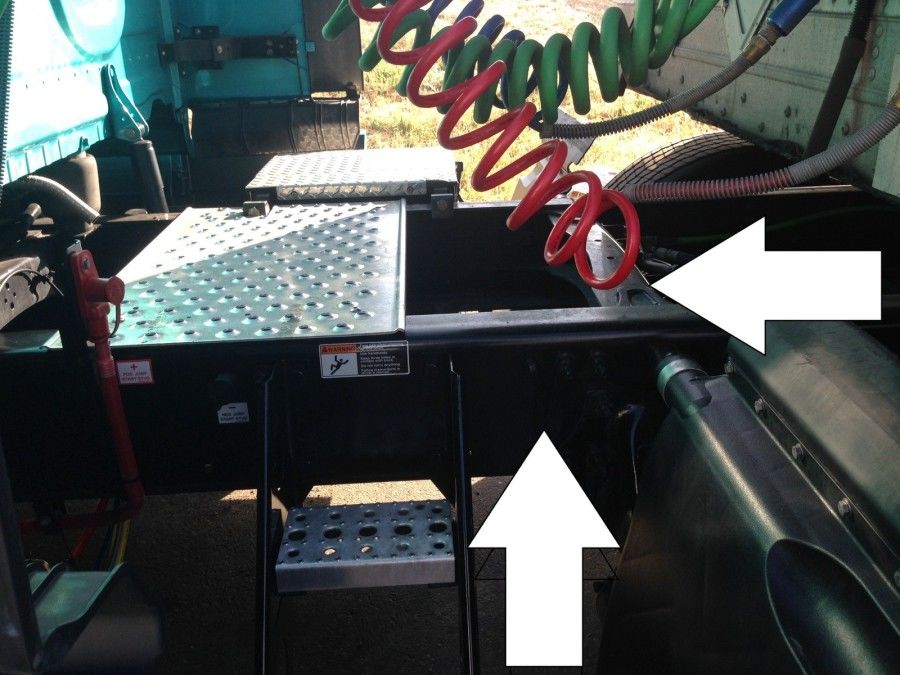

Cat Walk and Steps-

Cat Walk and Steps-

Properly Mounted and Secure. Not Not Cracked, Bent, or Broken. Clear of any loose objects.

Daniel's Tip: Easy item. Don't forget to state that they are clear of any loose objects.

Frame and Cross Members-

Frame and Cross Members-

Properly Mounted and Secure. Not Not Cracked, Bent, or Broken. There are no unauthorized holes or welds. No missing Cross Members.

Daniel's Tip: You can't miss that Frame, but the Cross Members can be easily forgotten. Bundle them up and be sure to state there are no missing Cross Members.

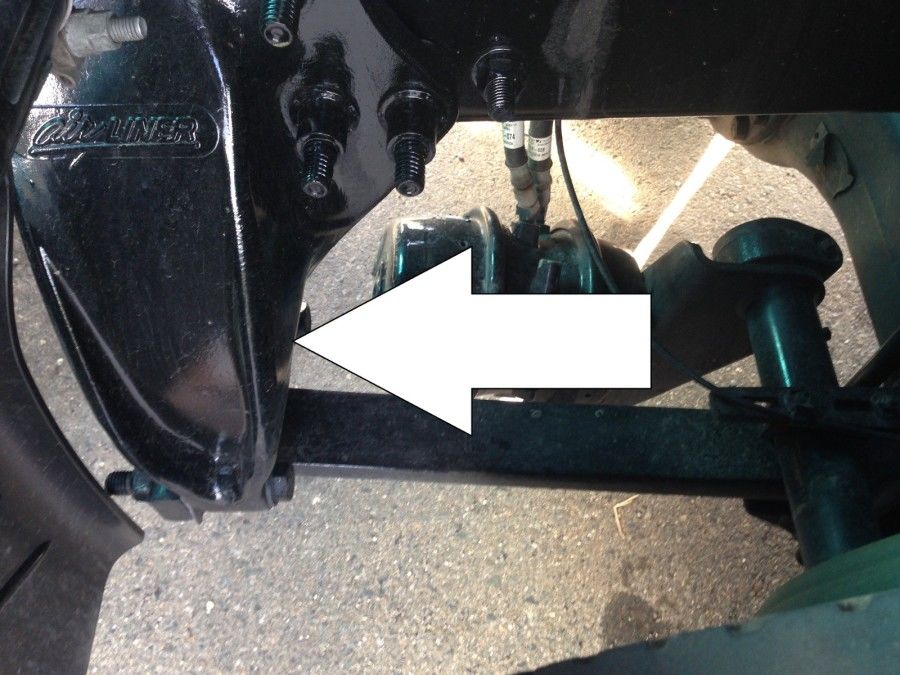

Torque Arm-

Torque Arm-

Properly Mounted and Secure. Not Not Cracked, Bent, or Broken.

Daniel's Tip: Easy item. Extremely straight forward.

Spring Mount-

Spring Mount-

Properly Mounted and Secure at both ends. Not Not Cracked, Bent, or Broken.

Daniel's Tip: Be sure to include "at both ends". Otherwise its a very easy item. Notice the difference between a Spring Hanger and a Spring Mount?

Spring Arm-

Spring Arm-

Properly Mounted and Secure at both ends. Not Cracked, Bent, or Broken.

Daniel's Tip: A Spring Arm is only one spring- unlike the Leaf Springs. Don't let anyone tell you otherwise because a lot of people have this confused. Don't forget to include "at both ends."

U-Bolts-

U-Bolts-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. None missing.

Daniel's Tip: Very simple item. Just be sure to say none are missing, that line is easily forgettable.

Shock Absorber-

Shock Absorber-

Properly Mounted and Secure at both ends. Not Not Cracked, Bent, or Broken. Not leaking.

Daniel's Tip: Don't forget to say "at both ends" and "not leaking". If it'll leak, it'll leak at the point where the top and bottom portion of the Shock meet - in the Middle.

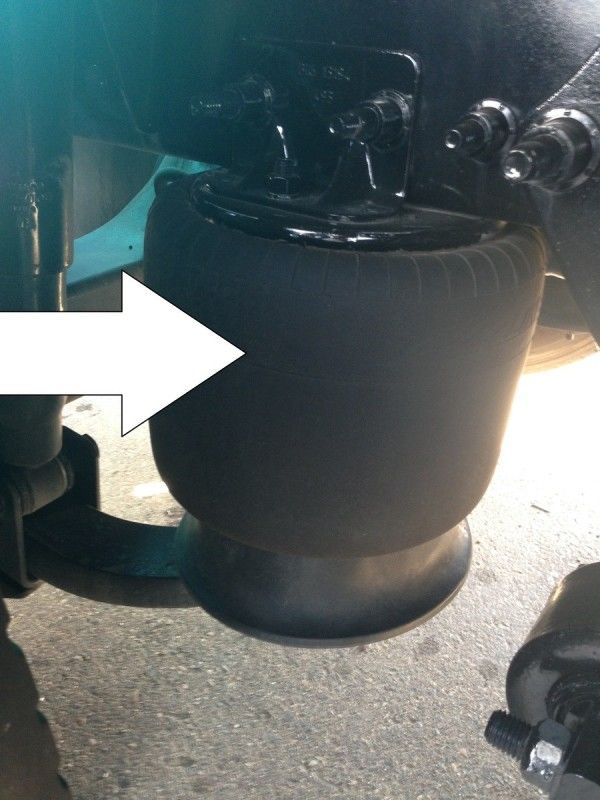

Air Bag-

Air Bag-

Properly Mounted and Secure at both ends. Not Cracked, Bent, or Broken. No Abrasions, Bulges or Cuts. Not leaking. No missing mounting bolts.

Daniel's Tip: Don't underestimate the Air Bag. Be sure to say its PMS at both ends. The top of the Air Bag is metal so give it a CBB. The actual Air Bag is rubber so give that an ABC. It is not leaking air and no missing mounting bolts. This is the one item that you must do a PMS, CBB, and ABC on!

Brake Hose-

Brake Hose-

Properly Mounted and Secure at both ends. No Abrasions, Bulges or Cuts. Not leaking air.

Daniel's Tip: Again, don't forgot to say "at both ends". The Hose is rubber so give it the ABC and not leaking air. You could combine the line with the Chamber but I prefer not to but its very easy to forget to mention the hose. When you're under pressure, you tend to forget the small things - like a hose.

HOS:

Hours Of Service

HOS refers to the logbook hours of service regulations.OOS:

When a violation by either a driver or company is confirmed, an out-of-service order removes either the driver or the vehicle from the roadway until the violation is corrected.

Brake Chamber-

Properly Mounted and Secure. Not Not Cracked, Bent, or Broken. Not leaking air.

Daniel's Tip: Easy item to inspect, don't forget to mention that it's not leaking air.

Slack Adjuster and Push Rod-

Slack Adjuster and Push Rod-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. With the brakes released and pulled by hand, the Push Rod should not move more than 1 inch.

Daniel's Tip: The Slack Adjuster and Push Rod are always combined. Please, be very careful with your words on this one. Say it exactly how I wrote it! Memorize that line.

Brake Drum-

Brake Drum-

Properly Mounted and Secure. Not Cracked, Bent, or Broken.

Daniel's Tip: Easy item to inspect. Just a simple PMS (properly mounted, secured) and CBB (cracked, broken, bent).

Brake Lining-

Brake Lining-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. No oil or debris. Friction Material is not worn dangerously thin.

Daniel's Tip: Remember, you're checking for oil or debris and for friction material on the Lining not on the Drum. People often mix this up. You must point exactly at the Brake Lining, like I have it in the picture.

Rim-

Rim-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. No unauthorized welds.

Daniel's Tip: Fairly simple item. Be sure to mention that there cannot be any unauthorized welds.

Lug Nuts-

Lug Nuts-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. There are none missing. No rust trails or powder residue. No cracks around the bolt holes.

Daniel's Tip: Rust trails could indicate loose bolts while powder residue and cracks around the bolts holes could be an indication of the bolts being over-tightened. Be sure to let the examiner know you're looking for rust trails or powder residue and no cracks around the bolt holes.

Axle Seal-

Axle Seal-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. Not leaking and filled to manufacturers specifications.

Daniel's Tip: Just be sure to say that its filled to manufacturers specifications.

Drive Tire-

Drive Tire-

No Abrasions, Bulges or Cuts to the tread or sidewalls. Tread depth is no less than 2/32 of an inch. Properly filled to manufactures specifications. Check it with an air gauge.

Daniel's Tip: Tires are a big deal! Be sure to look for Abrasions, Buldges or Cuts to the Tread and Sidewalls. Be sure to say it too. Drive tires cannot be less than 2/32 of an inch depth. You must say "of an inch", simply saying "2/32" is not enough. Properly filled to manufactures specifications and you absolutely must add that you check it with an air gauge! You don't have to physically check it with an air gauge on your exam, just mention that you would.

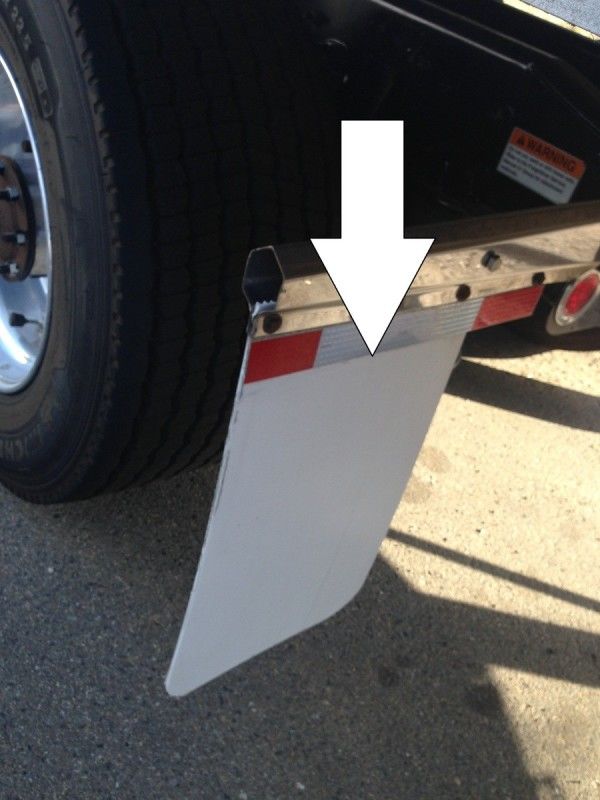

Mudflap-

Properly Mounted and Secure. Not Cracked, Bent, or Broken.

Daniel's Tip: Simple item. Just a sidenote, don't forget the Reflective Tape on your Mudflap when you do your Light Test.

Spacing-

Only if you're truck is equipped with duals! Check to see that there is proper space between the tires. There is nothing stuck between the tires.

Daniel's Tip: This only applies if you don't have Super Singles. Just let the examiner know you would check for proper space between the tires and making sure there's nothing stuck between them.

Super Singles:

A single, wide wheel substituted for a tandem (two wheel) assembly. The main benefit of a super single is a reduction in weight and lower rolling resistance which provide better fuel economy. The disadvantage is the lack of tire redundancy (or a 'backup tire' in case of a blowout) from which tandem wheels benefit. A tire blowout is more dangerous with a super single and can not be driven on.

OOS:

When a violation by either a driver or company is confirmed, an out-of-service order removes either the driver or the vehicle from the roadway until the violation is corrected.

Coupling Area

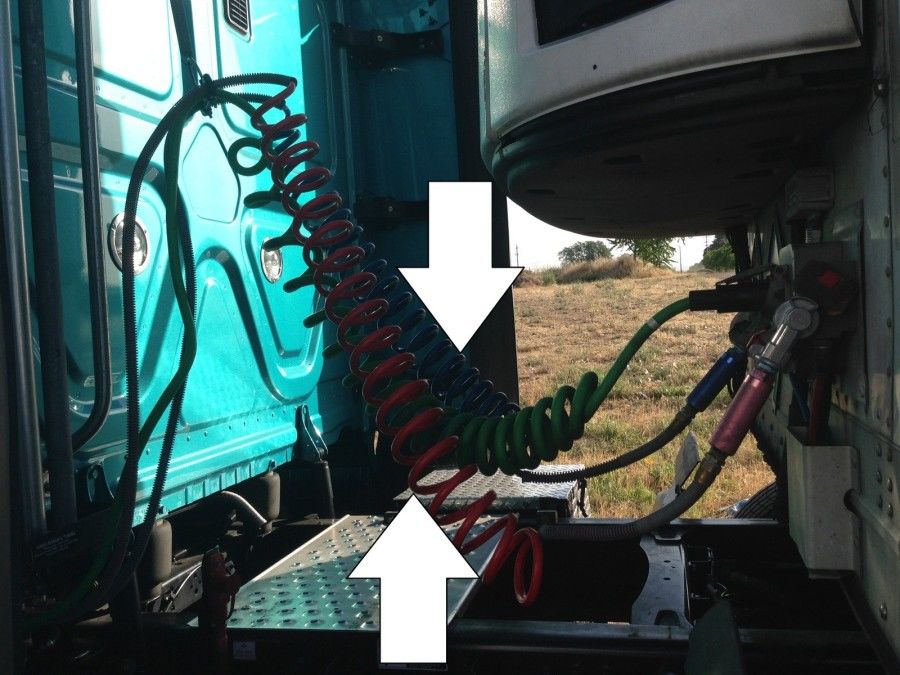

Electric Line-

Properly Mounted and Secure at both ends. No Abrasions, Bulges or Cuts. No exposed wires.

Daniel's Tip: Don't forget "at both ends". Its really easy to forget to say "No exposed wires." so really make that line stick so you won't miss it on the exam.

Air Lines-

Air Lines-

Properly Mounted and Secure at both ends. No Abrasions, Bulges or Cuts. Not leaking air.

Daniel's Tip: Don't forget to say "At both ends." Be sure to point at both the red and blue air line.

Glad Hands-

Glad Hands-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. Seals are in good condition, no cracks or signs of dry rotting. Not leaking air.

Daniel's Tip: Take an air line off during the test so you could show the examiner the seals.

Apron-

Apron-

Properly Mounted and Secure. Not Cracked, Bent, or Broken.

Daniel's Tip: The Apron is the front surface of the Trailer that the Fifth Wheel is beneath. Its the part of the trailer that doesn't have visible cross members and flat with few holes.

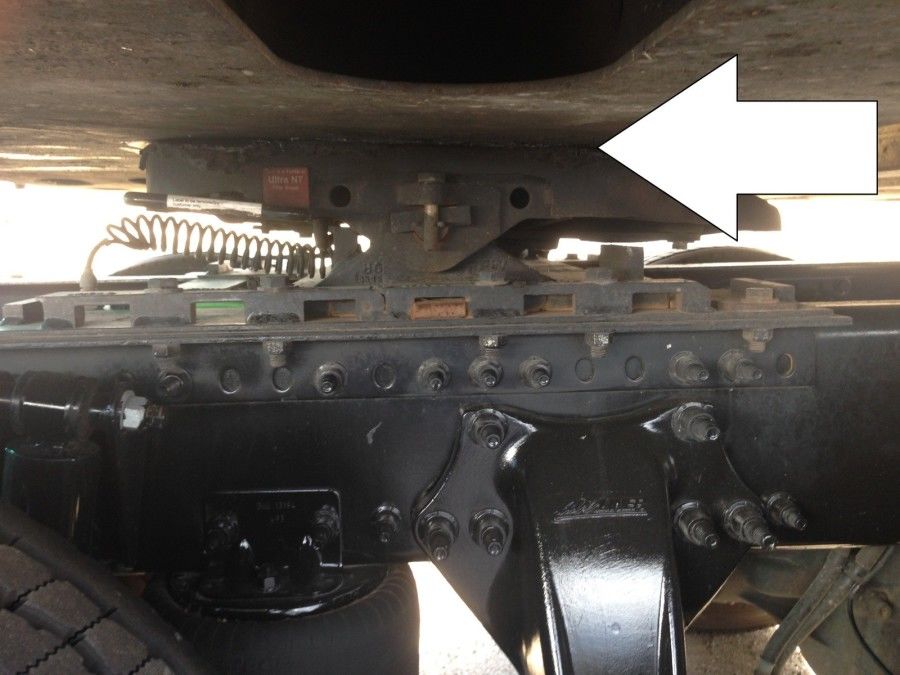

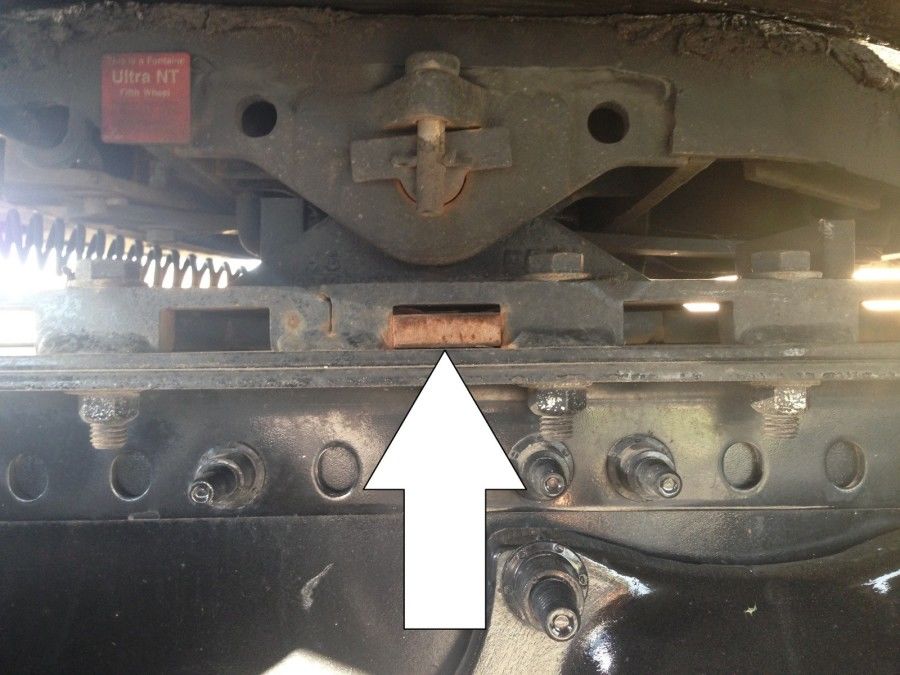

Skid Plate-

Skid Plate-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. Properly lubed.

Daniel's Tip: The Skid Plate is the top slippery surface of the Fifth Wheel. It must be properly lubed.

Gap-

Gap-

Check to make sure that there is no space between the Apron and Skid Plate.

Daniel's Tip: The Gap is not an actual item. Its the space between the Apron and the Skid Plate. There should be no daylight between the Apron and Skid Plate.

King Pin-

King Pin-

Properly Mounted and Secure. Not Cracked, Bent, or Broken.

Daniel's Tip: Can be easy to miss because you can't see it. But please don't miss something so important as the King Pin. Engrave this into your head.

Locking Jaws-

Locking Jaws-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. Fully locked around the King Pin.

Daniel's Tip: On your exam you must bend down and physically check those Locking Jaws, just like you should be doing every day several times. Be sure to say its fully locked around the King Pin.

Platform-

Platform-

Properly Mounted and Secure. Not Cracked, Bent, or Broken.

Daniel's Tip: The Platform is what the Fifth Wheel rests on. It goes Frame, then Platform, then Fifth Wheel. The Platform is easy to inspect, feel free to combine it with the Mounting Bolts. But again, I choose not to.

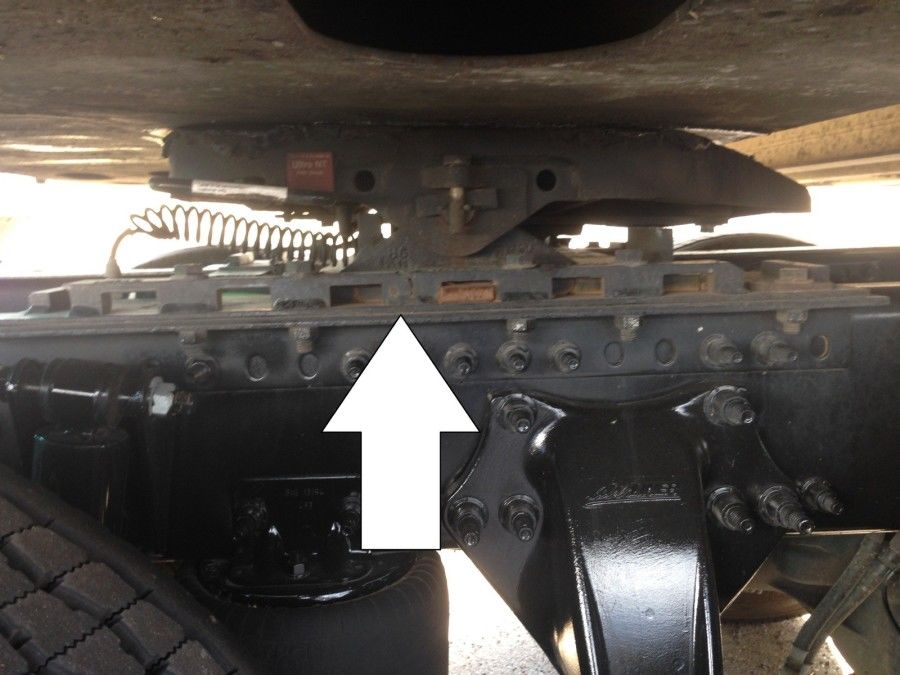

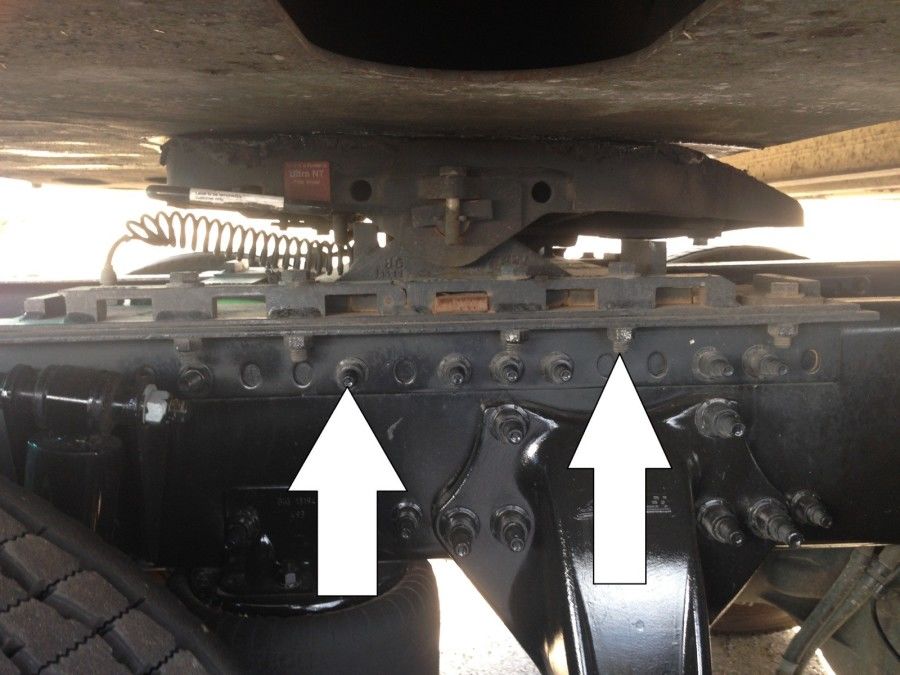

Mounting Bolts-

Mounting Bolts-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. None missing.

Daniel's Tip: Technically, you could combine this with the Platform but I choose not to. Up to you. Be sure to point at the bolts and don't forget to say none missing.

Release Arm-

Release Arm-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. Is in the fully locked position.

Daniel's Tip: The Release Arm is what allows you to disengage the Locking Jaws. The handle, or Arm, must be in the fully locked position. You must say that!

Sliding Fifth Wheel And Locking Pin-

Sliding Fifth Wheel And Locking Pin-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. Is in the fully locked position.

Daniel's Tip: Remember to point at the Sliding area and the Locking Pin. It must be in the fully locked position. You must say that!

Clearance-

Clearance-

Make sure that there is the proper space between the tractor mudflap and the trailer landing gear. So that they don't hit each other when making a turn.

Daniel's Tip: Clearance is by far the easiest to forget of everything in the entire test! I kid you not. Please engrave this into your head. You want to check the space between your mudflap and landing gear, so they don't hit each other on a turn.

HOS:

Hours Of Service

HOS refers to the logbook hours of service regulations.OOS:

When a violation by either a driver or company is confirmed, an out-of-service order removes either the driver or the vehicle from the roadway until the violation is corrected.

Trailer

Header Board-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. No holes or missing rivets.

Daniel's Tip: The Header Board is the front wall of the trailer. You must say that it cannot have any holes or missing rivets.

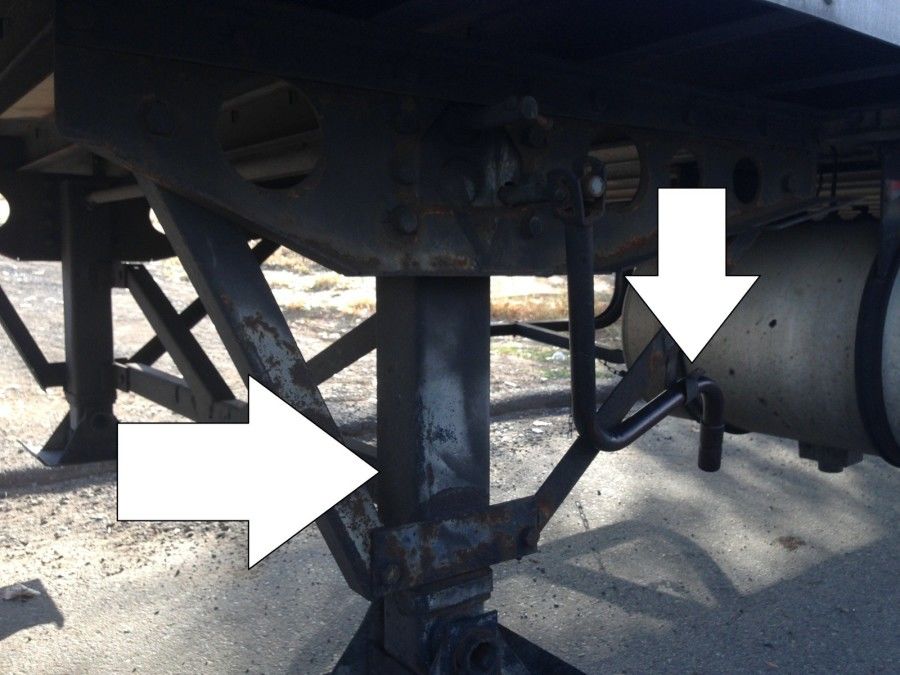

Landing Gear-

Landing Gear-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. Is fulled raised and the cradle handle is secure.

Daniel's Tip: The hardest thing about the Landing Gear is that handle. It must be in the cradle and secure. The Lading Gear must be fully raised.

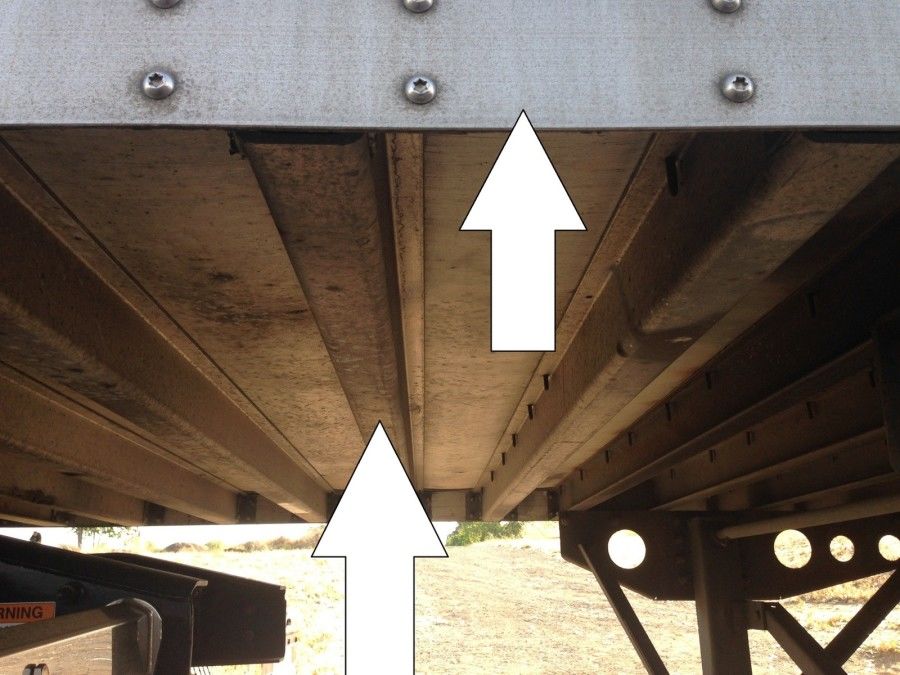

Frame and Cross Members-

Frame and Cross Members-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. No missing Cross Members.

Daniel's Tip: The Frame is the bottom portion on the walls of the trailer. Don't get that mixed up. The Cross Members go side-to-side throughout the trailer, there cannot be any missing.

Tandem Frame and Tandem Release-

Tandem Frame and Tandem Release-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. Release handle and locking pins are in the fully locked position.

Daniel's Tip: The Tandem Frame is the frame for the tandems. The Tandem Release is the actual handle that releases the Pins. You must also check the Pins, they must be in the fully locked position.

.

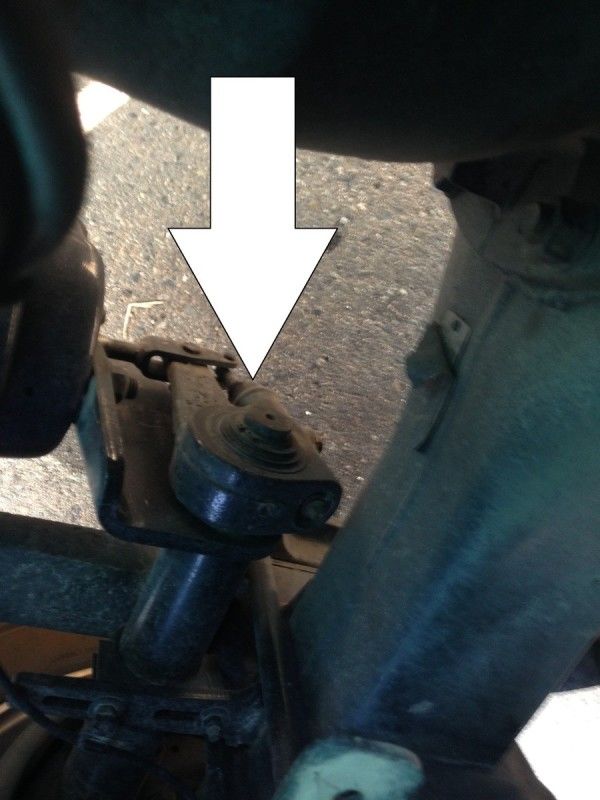

Shock Absorber-

Shock Absorber-

Properly Mounted and Secure at both ends. Not Cracked, Bent, or Broken. Not leaking.

Daniel's Tip: Don't forget to say "at both ends" and "not leaking". If it'll leak, it'll leak at the point where the top and bottom portion of the Shock meet - in the Middle.

Air Bag-

Air Bag-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. No Abrasions, Bulges or Cuts. Not leaking air. No missing mounting bolts.

Daniel's Tip: Don't underestimate the Air Bag. Be sure to say its PMS at both ends. The top of the Air Bag is metal so give it a CBB. The actual Air Bag is rubber so give that an ABC. It is not leaking air and no missing mounting bolts. This is the one item that you must do a PMS, CBB, and ABC on!

Brake Hose-

Brake Hose-

Properly Mounted and Secure at both ends. No Abrasions, Bulges or Cuts. Not leaking air.

Daniel's Tip: Again, don't forgot to say "at both ends". The Hose is rubber so give it the ABC and not leaking air. You could combine the line with the Chamber but I prefer not to but its very easy to forget to mention the hose. When you're under pressure, you tend to forget the small things - like a hose.

Brake Chamber-

Brake Chamber-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. Not leaking air.

Daniel's Tip: Easy item to inspect, don't forget to mention that it's not leaking air.

Slack Adjuster and Push Rod-

Slack Adjuster and Push Rod-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. With the brakes released and pulled by hand, the Push Rod should not move more than 1 inch.

Daniel's Tip: The Slack Adjuster and Push Rod are always combined. Please, be very careful with your words on this one. Say it exactly how I wrote it! Memorize that line. The ones in the back look a lot different than the ones on the Steer axle, but that shouldn't impact you on your performance.

Brake Drum-

Brake Drum-

Properly Mounted and Secure. Not Cracked, Bent, or Broken.

Daniel's Tip: Easy item to inspect. Just a simple PMS and CBB.

Brake Lining-

Brake Lining-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. No oil or debris. Friction Material is not worn dangerously thin.

Daniel's Tip: Remember, you're checking for oil or debris and for friction material on the Lining not on the Drum. People often mix this up. You must point exactly at the Brake Lining, like I have it in the picture.

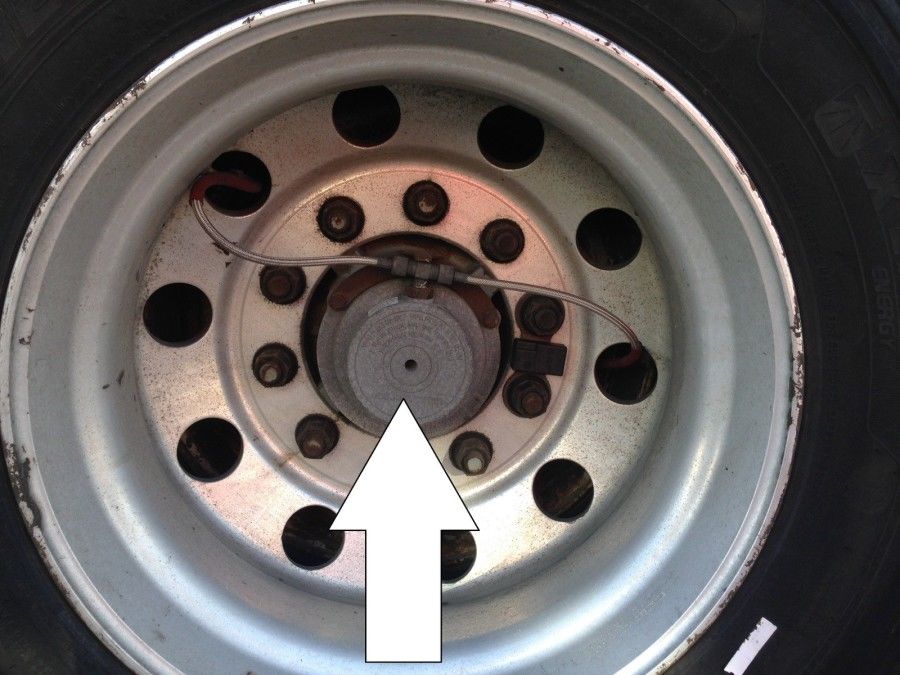

Axle Seal-

Axle Seal-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. Not leaking and filled to manufactures specifications.

Daniel's Tip: Just be sure to say that its filled to manufactures specifications.

Lug Nuts-

Lug Nuts-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. There are none missing. No rust trails or powder residue. No cracks around the bolt holes.

Daniel's Tip: Rust trails could indicate loose bolts while powder residue and cracks around the bolts holes could be an indication of the bolts being over-tightened. Be sure to let the examiner know you're looking for rust trails or powder residue and no cracks around the bolt holes.

Tandems:

Tandem Axles

A set of axles spaced close together, legally defined as more than 40 and less than 96 inches apart by the USDOT. Drivers tend to refer to the tandem axles on their trailer as just "tandems". You might hear a driver say, "I'm 400 pounds overweight on my tandems", referring to his trailer tandems, not his tractor tandems. Tractor tandems are generally just referred to as "drives" which is short for "drive axles".

Tandem:

Tandem Axles

A set of axles spaced close together, legally defined as more than 40 and less than 96 inches apart by the USDOT. Drivers tend to refer to the tandem axles on their trailer as just "tandems". You might hear a driver say, "I'm 400 pounds overweight on my tandems", referring to his trailer tandems, not his tractor tandems. Tractor tandems are generally just referred to as "drives" which is short for "drive axles".

HOS:

Hours Of Service

HOS refers to the logbook hours of service regulations.OOS:

When a violation by either a driver or company is confirmed, an out-of-service order removes either the driver or the vehicle from the roadway until the violation is corrected.

Rim-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. No unauthorized welds.

Daniel's Tip: Fairly simple item. Be sure to mention that there cannot be any unauthorized welds.

Trailer Tire-

Trailer Tire-

No Abrasions, Bulges or Cuts to the tread or sidewalls. Tread depth is no less than 2/32 of an inch. Properly filled to manufactures specifications. Check it with an air gauge.

Daniel's Tip: Tires are a big deal! Be sure to look for Abrasions, Buldges or Cuts to the Tread and Sidewalls. Be sure to say it too. Trailer tires cannot be less than 2/32 of an inch depth. You must say "of an inch", simply saying "2/32" is not enough. Properly filled to manufactures specifications and you absolutely must add that you check it with an air gauge! You don't have to physically check it with an air gauge on your exam, just mention that you would.

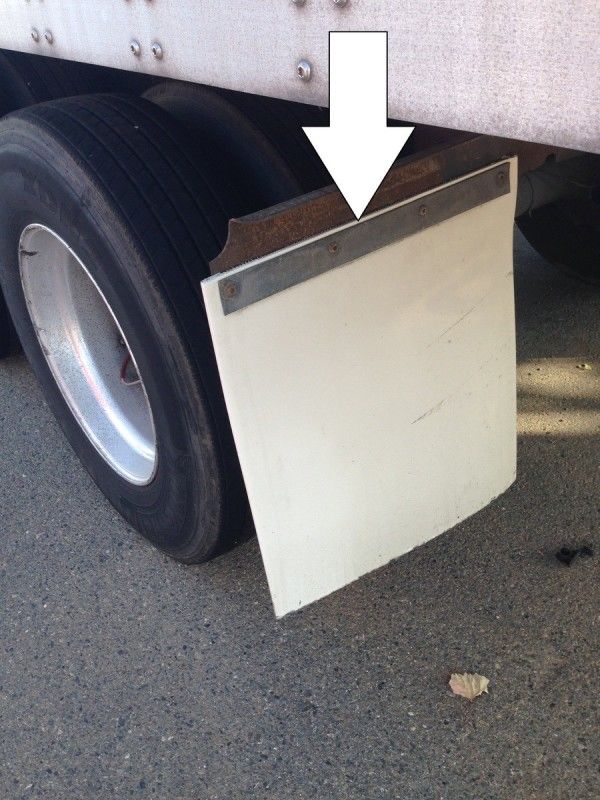

Mudflap-

Mudflap-

Properly Mounted and Secure. Not Cracked, Bent, or Broken.

Daniel's Tip: Simple item. Just give it a PMS and a CBB.

Spacing-

Spacing-

Only if you're truck is equipped with duals! Check to see that there is proper space between the tires. There is nothing stuck between the tires.

Daniel's Tip: This only applies if you don't have Super Singles. Just let the examiner know you would check for proper space between the tires and making sure there's nothing stuck between them.

Rear Door and Hinges-

Rear Door and Hinges-

Properly Mounted and Secure. Not Cracked, Bent, or Broken. Opens and close and latches properly. Door seals are not worn, torn, or dry rotted.

Daniel's Tip: You don't need to open the trailer doors to demonstrate that they open and close and latch properly. So keep that in mind. Just be sure to point out the Hinges and the Door seals and say the above.

Super Singles:

A single, wide wheel substituted for a tandem (two wheel) assembly. The main benefit of a super single is a reduction in weight and lower rolling resistance which provide better fuel economy. The disadvantage is the lack of tire redundancy (or a 'backup tire' in case of a blowout) from which tandem wheels benefit. A tire blowout is more dangerous with a super single and can not be driven on.

Light Check

Five locations that you must check your lights are:

Front of the Truck

Both sides of the Truck

Rear of the Truck

Both sides of the Trailer

Rear of the Trailer

The Five Functions are:

Left Turn Signal

Right Turn Signal

Four Way Flashers

High Beams/Low Beams

Brake Lights

--------When you start your Light Check, you should tell the examiner

that you will check all your:

Lights, Reflectors, Reflective Tape the same way.

Properly Mounted and Secure

Not Cracked, Bent, Broken

Clean and illuminated

The proper color of amber to the front and sides, and red to the rear.

Turn on your Marker Lights and Headlights.

Now walk around the entire truck and trailer and point out the lights Give the function of the light and the location.

You should then ask your examiner to help you check your Five Functions.

While you're sitting in the drivers seat, the examiner will stand to the front of the truck, then behind the trailer. He will then check your Turn Signals, Four Way Flashers and Brake Lights.

You must do each function at every location.

New Reply:

New! Check out our help videos for a better understanding of our forum features

Preview:

This topic has the following tags:

Driver Responsibilities Photos Pre-trip inspection (PTI) Truck Equipment Questions

TT On Facebook

TT On Facebook

You can now find a PDF printable version of this entire pre-trip inspection and a PDF checklist, both printable, in our Pre-Trip Inspection Study Guide or you can view them directly here:

-

PDF: Daniel's Pre-trip Inspection (Main Version)

-

PDF: Daniel's Pre-trip Inspection (Printable Version)

-

PDF: Daniel's Pre-trip Inspection Checklist (Printable Version)

We also have pre-trip inspection videos, checklists, and pre-trip inspection CDL practice tests.Hello TT! You're looking at yet another legendary thread done by me!

This is my Pre-Trip Inspection, done my way! This Pre-Trip is done on my truck and trailer. I physically took the pictures and edited them to my liking. These are not pictures taken off of Google. It is a complete Pre-Trip Inspection and features everything you'll need to know. I've been working on this for a long time and my hometime finally gave me the chance to finish it all up.

This is based off of Prime Inc.'s Pre-Trip Inspection procedure. Your companies Pre-Trip might vary slightly.

Here are our sections:

Engine Compartment

Drivers Door Fuel Area

Coupling System

Trailer (Please note in the type of suspension your trailer has)

Light Check

In-Cab Inspection and Brake Tests

You will absolutely have to do the Coupling System, Light Check, and In-Cab Inspection. Then they select for you to also do either the Engine Compartment, Drivers Door Fuel Area, or the Trailer. It could be either one. You will have a total of 4 sections that you must pass on your exam. So study extra-hard on those required sections.

As stated, these are solely based off of how I like to do the Pre-Trip. I give my personal opinions as well as some helpful tips.

Your Instructor's advice may vary. In the end, just do it the way your Instructor wants you to do it.

Pre-trip Inspection:

A pre-trip inspection is a thorough inspection of the truck completed before driving for the first time each day.

Federal and state laws require that drivers inspect their vehicles. Federal and state inspectors also may inspect your vehicles. If they judge a vehicle to be unsafe, they will put it “out of service” until it is repaired.

CDL:

Commercial Driver's License (CDL)

A CDL is required to drive any of the following vehicles:

HOS:

Hours Of Service

HOS refers to the logbook hours of service regulations.